For large corporations, procurement management is an art form unto itself. Do it well and you will gain a source of long-term competitive advantage. Do it poorly and you are at risk of paying too much for products — or potentially putting your entire operation in jeopardy.

There is a right way and a wrong way to do procurement. The writers at Management Enthusiast define the “5 R’s” of procurement strategy as follows. This blog will explain how these 5 R’s are directly relevant to print outsourcing and the various commercial print management models available from document outsourcing companies.

The Right Quality

“Right” is not always synonymous with “best.” The goal is to source a product that meets the performance specifications required at the lowest possible price. Spending for quality that isn’t required is a waste of company resources.

The Right Quantity

It’s tempting to over-purchase a critical item to ensure you never run out. However, this has many drawbacks from a procurement standpoint. Capital resources are needlessly tied up, items become obsolete and extra costs are incurred for storage.

The Right Price

The cheapest price does not always result in the lowest Total Cost of Ownership. Items purchased based on price alone become exorbitantly expensive if they result in waste, product returns or production complications down the road.

The Right Time and Place

It rarely makes sense to procure something months before it is needed. Warehousing costs, damage and pilferage will slowly eat away at the value proposition behind your purchase. Likewise, it’s generally wise to take delivery of your purchase where it will actually be used rather than pay redundant shipping and handling costs later.

The Right Source

The last “R” covers a range of intangibles. For example, a supplier with redundant manufacturing facilities can help you sidestep supply chain interruptions while a partner who continuously invests in the latest industry technologies can ensure that you never fall behind the competition. Always look beyond the purchase order specifications to identify a supplier partner who can add value in other ways.

Outsourcing Print Management and the 5 R’s

It’s been estimated that printed materials account for roughly 20% of the average corporation’s annual marketing budget. In pursuit of the 5 R’s, many organizations create in-house print centers believing they can do it better, faster and cheaper internally than by outsourcing printing services through print procurement companies. However, is this necessarily true?

Taylor commissioned an independent research firm to survey a sample of 152 procurement, financial and operations leaders to better understand how print management outsourcing factors into their annual plans. Three findings stood out in our analysis. As you will see, a majority of respondents believe the 5 R’s are best achieved by outsourcing printing services through managed print services providers instead of continuing to operate an internal print operation.

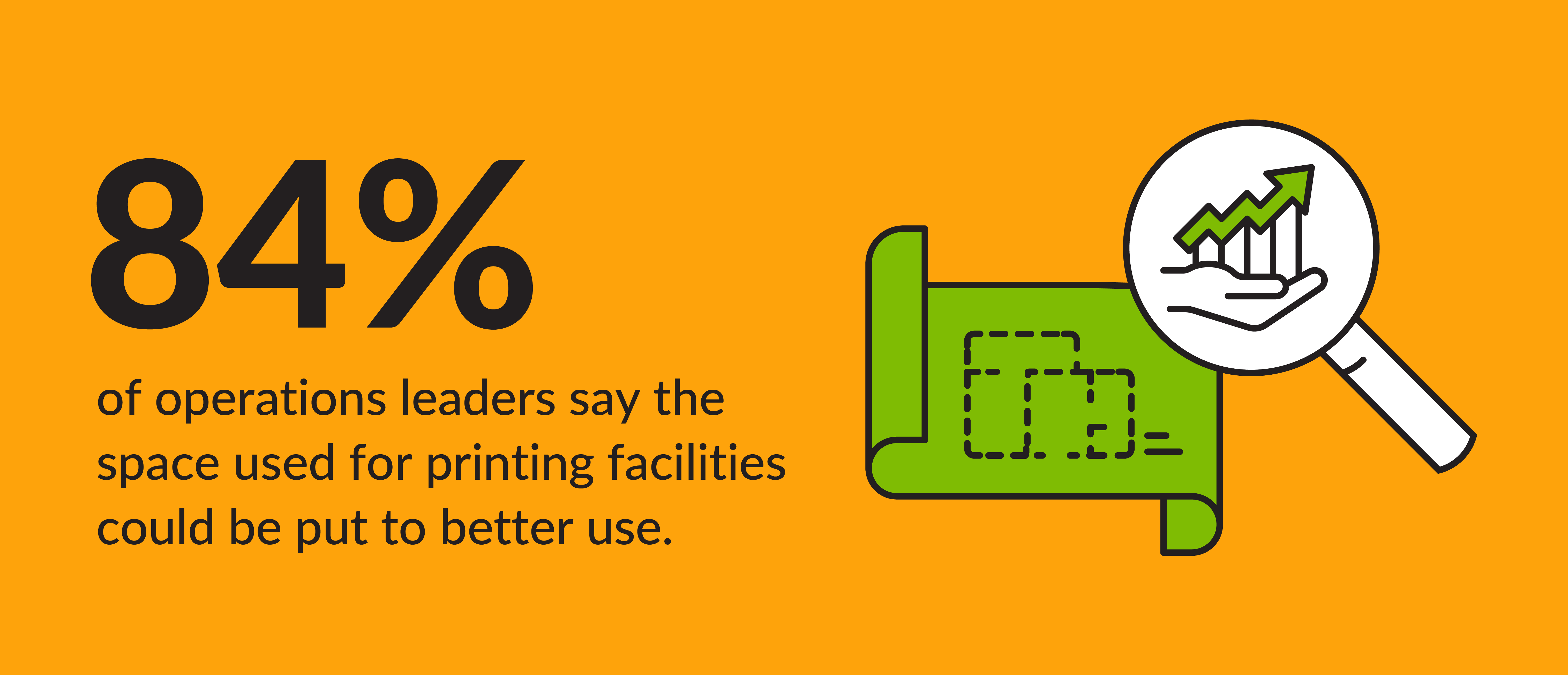

1: In-house print centers are considered a poor use of space

Key takeaway: Space management best practices seek to ensure that the highest possible return is derived from every dollar invested in real estate. This finding suggests that internal print shops actually reduce the overall ROI on real estate for most organizations, such as when compared to using an outsourced print service for strategic print management.

2: Quality suffers when a print industry specialist is not used

Key takeaway: Practically speaking, it is impossible for most organizations to justify ongoing investments in state-of-the-art printing technology for in-house print operations. Over time, the in-house technology lags and print quality falls behind the outsourced printing services available from document outsourcing companies.

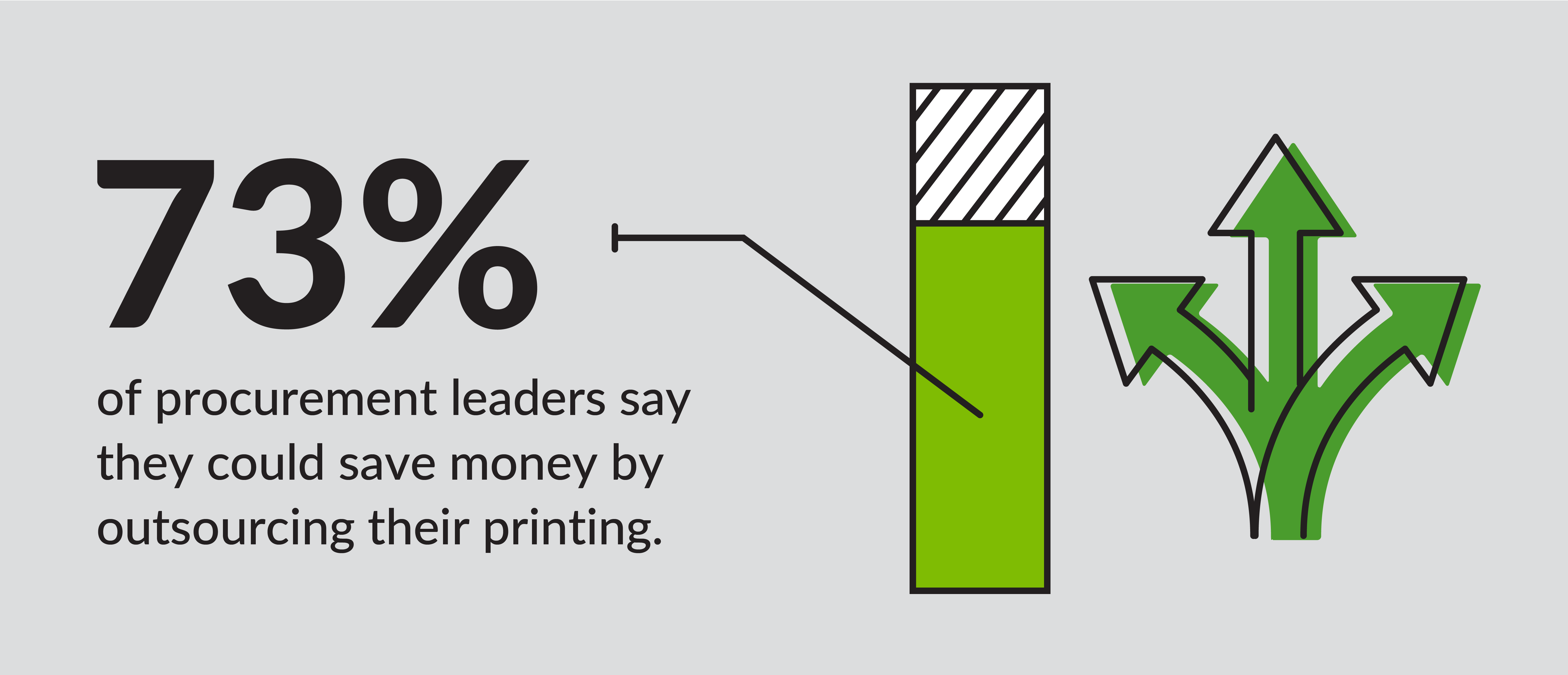

3: In-house print shops end up costing more

Key takeaway: Above all, in-house print shops are intended to be more cost-effective than print management outsourcing. However, a majority of procurement leaders admit this is not the case — which calls into the question the strategy behind internal print management operations.

These are just a few of the findings captured by this Taylor survey on print management.

Click here to download an infographic summarizing the entire study.

The margin of error was +/- 6% at the 95% confidence level.

Print Management Outsourcing Models

Taylor is one of the largest global print and communications companies in North America. Print management outsourcing is among the many value-added services Taylor provides.

However, no two situations are exactly alike. There are a variety of commercial print management models that you could consider to serve your needs.

Dedicated On-Site Support

A print outsourcing partner can assume control of your organization’s on-site print shop. In this model, your outsourced print service takes on management responsibility for space, people, equipment, process and inventory.

Copy Center Hybrid

This model combines outsourcing print management with in-house capabilities. For example, an on-site concierge provided by your outsourced print service assists internal customers with small, fast-turn projects. Meanwhile, more complex print jobs are routed to your print outsourcing partner’s production network, typically via an online print management portal.

Outsource with Local Partner Support

In this scenario, your organization’s in-house print shop is shut down completely. Small, same-day projects are handled by a local provider. Meanwhile, all other jobs are ordered through your outsourced print management partner’s online print management portal.

Total Outsource

In a total outsourcing model, your organization’s in-house operation is shut down and no local support partner is engaged. All requests are submitted to your print management outsourcing partner via an online print management portal.

Outsourcing Print Management for Organizations Nationwide

To learn more about Taylor’s print outsourcing and commercial print management models, contact one of our document management specialists. From healthcare managed print services to print management outsourcing strategies for manufacturers, financial services firms and more, Taylor is one of the leading print outsourcing companies in North America today.