It’s no secret that overall demand for commercial print solutions in the U.S. has changed as more communications and transactions are delivered by digital means. Nonetheless, commercial print sourcing remains a big economic driver nationwide. Corporate print suppliers in the U.S. still generate revenues of more than $75 billion annually and employ over 360,000 employees, making it one of the largest onshore manufacturing industries in the U.S.

As significant as print management strategies are to the U.S. economy, they are surpassed by the volume of commercial print sourcing that originates in the Asia-Pacific region. In 2023, roughly 40% of all revenue related to global print services was generated by Asia-Pacific companies, with China accounting for the dominant share.

However, these trends are now subject to significant disruption. With the tariffs recently levied on U.S. trading partners worldwide, the cost of purchasing commercial print solutions from overseas will likely increase. Indeed, the tariffs for print outsourcing solutions via China specifically may reach triple-digit percentages, leading to more onshore manufacturing and increased commercial print sourcing from U.S.-based corporate printing vendors. Conversely, the cost of raw materials (e.g., paper and ink) imported by U.S. corporate print suppliers may also rise sharply, potentially working against the trend toward onshore commercial print production.

How will all of this affect the commercial print management strategy of a typical U.S. business? What should American companies that rely on commercial print solutions do when tariffs disrupt global supply chains? The answer to that question depends on many factors, such as:

- The type and volume of enterprise printing solutions purchased.

- Whether outsourced printing services are sent offshore or remain in the U.S. as onshore manufacturing.

- The company’s willingness to explore onshore commercial print production as an alternative to print outsourcing

This blog will explore how tariffs affect the supply chain of the many U.S.-based print partners who deliver print management services. It will also highlight the key questions to ask a corporate print supplier about their tariff response and how you can mitigate risk of supply chain disruption.

How do tariffs affect the supply chain for commercial print management?

Given the sheer volume of imported raw materials currently used by corporate print partners nationwide, supply chain tariffs will likely impact onshore commercial print production to a significant degree. Consider that onshore manufacturing of global print products commonly requires one or more of the following inputs.

- Statista reports that roughly 10-12% of paper and paperboard consumed in the U.S. is imported. The top three sources are Canada, China and Mexico — all countries potentially subject to substantial supply chain tariffs.

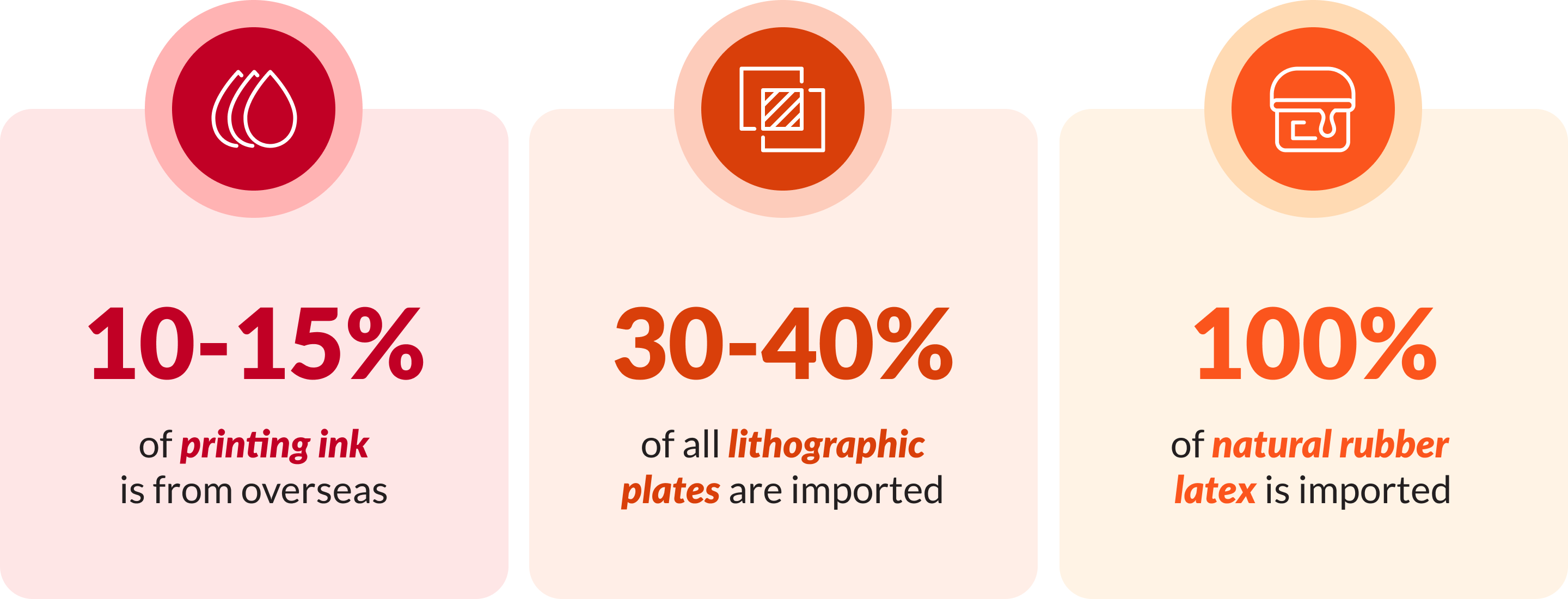

- The ink used by commercial print management services in the U.S. is often imported. IndexBox estimates that 10-15% of printing ink consumed nationwide is from overseas with Japan, the United Kingdom and Canada being the top sources by dollar value.

- Flexible polyvinyl chloride film, or PVC, is commonly used by print partners for both signs and graphics and labels and packaging. IndexBox reports that 15% of all PVC consumed in the U.S. each year is imported, much of it from China, Taiwan and Canada.

- The most current data from Abrams suggests that imports account for 30-40% of all lithographic plates consumed domestically with China being the single largest source. Lithography accounts for the largest share of print management solutions provided by U.S.-based corporate print suppliers.

- WITS notes that the U.S. imports 100% of natural rubber latex consumed domestically. Used by commercial print management providers for adhesives, binding glues and paper coatings, natural latex is most often imported from Guatemala, Vietnam and Thailand.

What questions should I ask my print vendor about tariffs?

Clearly, the effect of tariffs on the commercial print management supply chain in the U.S. varies widely by the type of raw materials being used. It also depends on whether onshore manufacturing resources are utilized or if print outsourcing strategies have sent the work offshore.

These six questions offer a good place to start with any corporate print supplier. Your ultimate goal should be to determine how tariffs affect the supply chain for your commercial print solutions and whether your corporate printing vendor is truly prepared for what lies ahead.

-

What specific tariffs are affecting your commercial print management operations?

By asking your provider about the specific tariffs they are dealing with, you can gain a clearer picture of the challenges they — and you — may face going forward.

-

What measures are you taking to mitigate the impact of print industry tariffs?

Are they sourcing materials from alternative suppliers in countries not affected by tariffs? Are they negotiating better terms with existing suppliers to offset the increased costs? By understanding their mitigation strategies, you can assess their ability to continue delivering high-quality printed products at competitive prices.

-

How are tariffs affecting your pricing?

Ask your corporate print supplier how tariffs are affecting their pricing structure. Are they implementing price increases to cover the additional costs? If so, how significant are these increases? Understanding the financial impact of tariffs on your print partner can help you budget more effectively for corporate print solutions.

-

Should we plan for lead time changes due to tariffs?

In addition to cost increases, tariffs can also affect lead times for printed products. Ask your corporate printing vendor if they are experiencing any changes in lead times due to tariffs. Are they able to maintain their usual turnaround times or should you expect delays? Knowing this information can help you plan your projects more effectively and avoid last-minute surprises.

-

Are your commercial print solutions created with onshore manufacturing?

Raw materials aside, it is entirely possible that your corporate print supplier utilizes outsourced printing services for some of the commercial print solutions that you purchase. Some of these services, in turn, may be provided by offshore print suppliers. If you aren’t absolutely certain that the commercial print you are buying is manufactured at onshore commercial print production facilities, now is the time to ask. If not, see if they are open to onshoring print production to facilities in the U.S. to help insulate you from the potential impact of tariffs.

-

What is their plan to communicate tariff-related changes to you?

Effective communication is key to managing the impact of tariffs. Your corporate print supplier should provide regular updates on pricing, lead times and supply chain issues. They should also have a dedicated point of contact for your tariff-related inquiries. Without these measures in place, it may prove difficult for you to stay informed and make the decisions your business needs to thrive in a time of uncertainty for the global print management industry.

Taylor: Onshore Commercial Print Production That Mitigates Tariffs

Taylor is among the largest providers of commercial print solutions in North America, possessing a massive print production footprint within the U.S. As a true single-source print vendor, we deliver printing and fulfillment services across the entire spectrum of print with the vast majority of it produced through onshore manufacturing:

- Commercial print

- Corporate identity and branding materials

- Custom book printing

- Custom packaging and labeling

- Customer communications management solutions

- Document management services

- Lenticular printing

- Signs, graphics and brand experiences, and more

However, in addition to a business model focused on onshore commercial print production, Taylor is taking proactive steps to minimize the impacts when tariffs disrupt global supply chains.

However, in addition to a business model focused on onshore commercial print production, Taylor is taking proactive steps to minimize the impacts when tariffs disrupt global supply chains.

- Taylor’s international sourcing teams are assessing and shifting, where possible, all offshore purchases to countries where cost and supply are the most protected.

- A third-party tariff consultant has been retained to help Taylor build efficient customs clearance processes. This will ensure compliance and prevent delays in getting our customers the printed products they need.

- Taylor is developing disciplined customer pricing strategies that will fully leverage the work performed in points 1. and 2. above. Our primary goal is to isolate and minimize cost increases to our customers.

Looking for a print partner who can deliver the commercial print solutions you need as tariffs disrupt global supply chains? Is onshoring print production a strategic priority for your business? Contact a Taylor representative to learn more about our enterprise printing solutions and onshore manufacturing footprint.

.jpg)

.jpg)

.jpg)