Our recent blogs on the topic of gift cards have generally focused on gift card security, such as gift card draining scams, and the trend toward more sustainable gift cards including non-plastic gift cards. For this blog, we look at custom gift card printing and how a gift card manufacturer can elevate a retail brand through the use of special gift card printing techniques.

In today's hyper-competitive retail landscape, brands are constantly seeking ways to stand out from the competition. Customized gift cards and innovative gift card printing methods not only help to differentiate retail brands but can also elevate the perceived value of the gift card itself.

This blog touches on some of the finishes and embellishments that are being used for custom-printed gift cards. Everything from lenticular 3D printed gift cards and embossing to foil, glitter, fragrances and more are helping retail brands to change consumer perception when marketing gift cards.

How are gift cards manufactured?

We begin with a review of how gift cards are manufactured. Until recent years, gift cards were generally made from PVC (polyvinyl chloride) plastic, long known for its durability and flexibility. However, shifting consumer sentiment has fueled demand for alternatives to plastic gift cards. These more eco-friendly gift cards are typically made from durable, paper-based card stock.

Print substrate aside, the manufacturing steps required for PVC and non-plastic gift cards are similar.

- Gift card printing involves the reproduction of logos, artwork and other required graphics onto the gift card surface by the gift cards’ manufacturer. Advanced digital printing techniques are often used to achieve crisp, vibrant images.

- The printed design is then protected with a finishing layer to ensure durability. Two primary types of finishing layers are commonly applied to gift cards: UV coatings and laminations. A UV coating involves the application of a thin layer of clear ink over the printed image, making it more resistant to scratches. Lamination, on the other hand, involves adding an additional layer of plastic over the printed image, sealing and protecting it. Both UV coatings and gift card laminates are generally available in matte, satin and gloss finishes.

- After the printing and finishing processes, the card is cut into its final shape and size. Precision die cutting machines are used to ensure that each card is uniform and meets the required dimensions.

- The next step involves the addition of unique identifiers such as barcodes, magnetic stripes or QR codes. These identifiers are crucial for the activation of the gift cards. The numbering process must be precise to avoid any duplication and ensure that each card is unique.

- Gift card security is a critical aspect of the gift card manufacturing process. To prevent fraud and tampering, security features are incorporated into the cards and card carriers. For example, tamper-evident labels and scratch-off panels can be added to protect the card numbers and activation codes.

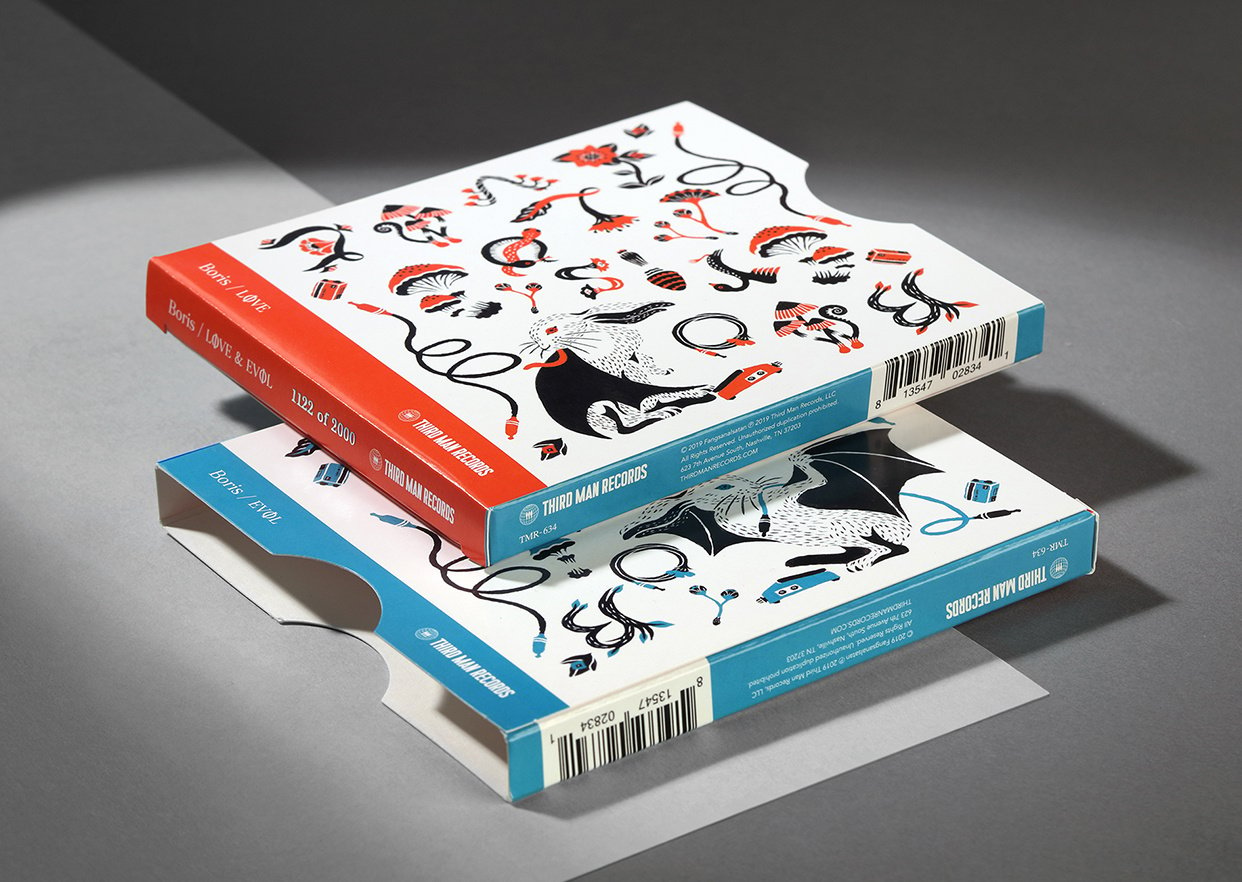

- The gift card fulfillment process isn’t complete until the gift cards are packaged and prepared for final distribution. Custom-printed gift card boxes can elevate the presentation and perceived value of the gift cards while also enhancing security. Retailers often invest in creative packaging when marketing gift cards to make the gift-giving experience more special.

What custom gift card printing techniques are possible?

Special gift card printing methods can significantly elevate the perceived value of gift cards through the addition of interesting tactile and visual embellishments. To gain that competitive advantage in the marketplace, retail brands sometimes ask their gift card manufacturers to “think outside the box” and create custom-printed gift cards that are truly unique. The following techniques are often seen in the marketplace.

Lenticular 3D Printed Gift Cards

Lenticular printing is a process through which the viewer experiences the illusion of depth or motion when the printed piece is viewed from different angles. Lenticular gift cards are an ideal application of this type of print technology. Disney has used lenticular gift cards with 3D printed gift card effects to bring its beloved characters to life, creating an element of surprise and delight in recipients.

Foil Stamping

Foil stamping involves applying metallic foil to the surface of the gift card, creating a shiny and sophisticated effect. Starbucks has been known to use foil stamping on its gift cards to add a touch of elegance to the finished piece.

Glitter

Adding glitter to the gift card printing process can create a sparkling, festive finish. Bath & Body Works often incorporates glitter into its holiday-themed gift cards, making them perfect for special gift-giving occasions.

Embossing

Embossing involves creating a raised design on the surface of the gift card, adding texture and depth. A custom-made die is pressed into the gift card surface to produce the raised impression. Embossing is often associated with luxury and quality. Nordstrom, as one example, is known to highlight its logo with embossing to create a premium feel.

Soft-Touch Aqueous Finishes

Soft-touch gift card finishes provide a velvety texture that feels luxurious to the touch. Sephora uses soft-touch finishes on gift cards to enhance the tactile experience and convey a sense of quality.

Fragrances

Infusing gift cards with fragrances can create a multi-sensory experience. Victoria's Secret has experimented with scented gift cards that release a pleasant aroma when opened.

Customized Gift Cards in Unique Shapes

Die cutting can be used to create custom-printed gift cards in nearly any shape. Logo-shaped gift cards are common while Target has offered custom-shaped gift cards with holiday-themed designs to commemorate special occasions.

Custom Gift Card Printing From Taylor

Taylor is one of the leading gift card manufacturers in the world with decades of experience in customized gift cards and custom gift card printing. A provider of both plastic gift card printing and paper gift card printing, Taylor creates custom-printed gift cards utilizing all of the techniques described above.

- As retailers seek more sustainable gift cards, Taylor has produced over 2.6 billion paper gift cards to date — and growing. In doing so, we have helped accelerate consumer adoption of non-plastic gift cards.

- Taylor’s expertise with lenticular printing, and lenticular gift cards in particular, is unrivalled in the industry.

- Efforts to create eco-friendly gift cards can be wasted if non-recyclable embellishments are applied to sustainable gift card substrates. That’s why Taylor offers 15 different print enhancements that do not adversely impact the recyclability of a paper-based gift card. Choose from fragrances, foil and glitter to embossing, Cast & Cure®, soft-touch and more.

- Taylor leads the way in tamper-evident gift card packaging that is specifically engineered to deter gift card scams — such as gift card draining — before they occur.

Looking for ways to raise your brand’s profile in the retail marketplace? Contact a Taylor representative to learn about our expertise with custom-printed gift cards.