.png)

Taylor delivers durable HVAC labels, nameplates, warning labels, and kits with regulatory compliance plus U.S./Mexico production, manuals, and tech do...

Taylor manufactures pressure-sensitive labels that deliver and impactful and reliable product identification. Our pressure-sensitive labeling solutions combine the aesthetics of intricate designs the durability and functionality of long-lasting adhesives and materials.

Taylor manufactures pressure-sensitive labels that meet performance standards and

enhance your brand identity.

A pressure-sensitive label is a label that adheres to a surface through the application of pressure. They form a strong bond with nearly any product or packaging type and do not require water, solvents or heat activation to do so. They are also referred to as self-adhesive labels or PS labels.

Pressure-sensitive labels can be applied to surfaces such as glass, plastic, metal, cardboard, and even textured or curved containers, and are ideal for any business that requires their labels to quickly and reliably adhere to a wide range of products and shapes.

This versatility makes pressure-sensitive labels a perfect option for products in industries such as grocery, food and beverage, automotive, pharmaceuticals, cosmetics, electronics and more.

Pressure-sensitive labels are easy to apply and come in a wide range of material and design options. Understanding the

different types of pressure-sensitive labels and their construction is important in using them to their full potential.

Laminates and topcoats give your labels extra protection against UV exposure, moisture, chemicals and abrasion. They’re available in a variety of materials and thicknesses depending on the additional protection and unique characteristics your labels require.

Pressure-sensitive label inks vary based on specific application needs. Your label inks must retain legibility and colorfastness throughout its intended lifespan. They can be fade-resistant, reflective, temperature-sensitive and feature anti-counterfeiting technology to fight fraud.

Paper or synthetic substrates, or facestocks, are the top layer of pressure-sensitive labels where your graphics and text are printed. They can be made from a range of papers, films and specialty stocks depending on the levels of adhesion and types of legibility your products require.

Adhesives are positioned beneath the facestock and bond securely to surfaces when pressure is applied. Your choice of adhesive depend on surface types and product requirements. Choosing the right adhesive ensures labels perform as expected, whether that means easy removal or enduring harsh conditions.

The liner is the bottom layer that protects the label's adhesive until it is ready to be applied. They come in a variety of film and paper options. When you’re selecting the liner best for your labels, adhesive type, storage conditions and whether they will be dispensed manually or via machine must be considered.

Taylor manufactures custom pressure-sensitive labels for a variety of surfaces, including plastic, glass, metal, corrugate, and

wood, and are used across industries such as agriculture, automotive, beverages, food, household products, nutraceuticals and

personal care.

Pressure-sensitive labels are a great choice for prime and product labels. They can serve as the main branding and informational labels on retail packaging, point-of-sale (POS) and promotional product packaging, and shelving, windows and display materials.

Product identification labels (PID) and price lookup labels (PLU) rely on pressure-sensitive labels for their traceability and tamper-evident features and ability to adhere to produce and packaging types that include cartons, clamshells and temperature-sensitive containers.

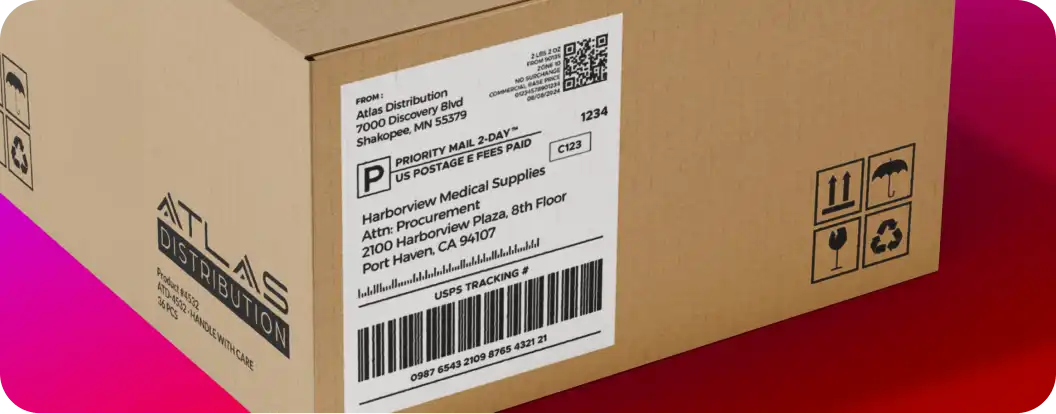

Pressure-sensitive labels adhere securely to corrugate, plastic, metal and more, and keep shipping information legible through all phases of delivery. Whether you're printing barcodes, tracking numbers or instructions, pressure-sensitive labels support logistics and reduce your line-down risk.

From inspection tags to lot tracking, pressure-sensitive labels help maintain compliance and traceability throughout your distribution network. They’re ideal for quality control applications, offering strong adhesion and reliable performance across diverse packaging materials.

Thermal labels come in two types: direct and thermal transfer. Direct thermal is ideal for short-term applications, while thermal transfer is better for longer lasting labels. Both types are pressure-sensitive and offer fast, cost-effective printing with excellent scannability.

Smart labels combine RFID, QR codes and barcodes for tracking and data access. These pressure-sensitive labels increase visibility and efficiency across your operations by enabling wireless identification, smartphone scanning and compatibility with legacy systems all in one compact format.

Pressure-sensitive labels can be designed specifically for expanded content labeling (ECL), as they can be securely applied to a wide range to packaging where more detailed information is needed on the label. They’re commonly used when regulatory, safety or multilingual content is required.

Pressure-sensitive labels can be used for tamper-evident applications designed to show visible signs of interference if a product has been opened or altered. These labels are essential for industries where product integrity and consumer safety are top priorities.

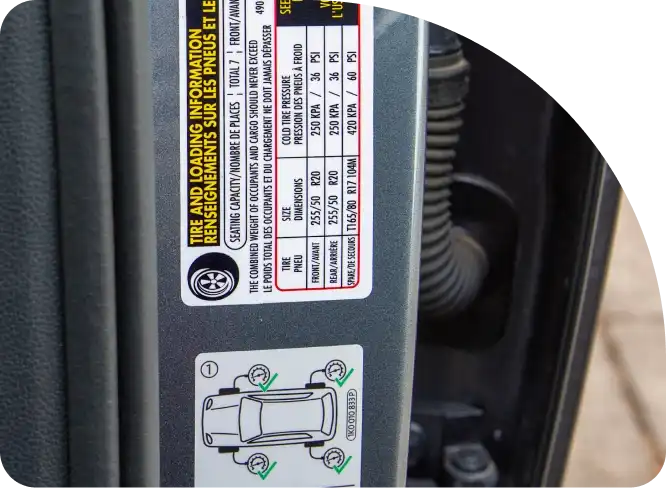

Durable pressure-sensitive labels withstand extreme temperatures, moisture, chemicals and abrasion. When it comes to labeling tools, machinery, automotive parts or outdoor equipment, these labels maintain legibility and adhesion in the harshest conditions.

Print-on-demand pressure-sensitive labels allow you to produce exactly what you need, when you need it. With digital platforms that support variable data, mass customization and fast turnarounds, you can quickly respond to market changes, personalize products and reduce waste.

Pressure-sensitive labeling is a high-quality, versatile and efficient way to label products. Pressure-

sensitive labels combine aesthetics with functionality, adhere to nearly any surface, and make the

application process faster and easier.

There are many reasons pressure-sensitive labels are used so extensively by nearly every industry.

Taylor’s pressure-sensitive label manufacturing capabilities meet diverse product labeling needs. We produce pressure sensitive labels for smaller businesses and large corporations alike, printing short, medium, and long runs of custom and stock pressure-sensitive labels.

Taylor has more than 100 years of labeling experience and a team of in-house engineers focused on improving label performance.

We leverage advanced printing technologies to create custom pressure-sensitive labels that enhance brand identity and product appeal.

Our printing methods and technology allow us to accommodate both short-run and medium run orders, as well as larger long-run enterprise projects.

A popular method for producing pressure-sensitive labels, particularly for large-volume orders requiring consistent quality and vibrant designs. Flexography excels at handling a wide range of face stocks and adhesives, making it suitable for both standard and custom label applications.

A leading option for producing pressure-sensitive labels, especially for businesses seeking flexibility, faster turnaround times and customization. Digital printing can handle a wide variety of facestocks and substrates, making it a cost-effective choice.

Valued for its ability to deliver exceptionally sharp, consistent imagery, especially on high-volume label runs. Offset printing provides high-quality, cost-effective pressure sensitive labels that enhance product branding.

A great technique for pressure- sensitive labels that require high-visibility graphics or bold text. This method supports a variety of face stocks, including films, foils and specialty materials, enabling brands and product manufacturers to achieve custom looks.

Enables unique information or graphics to be printed on each label, making it ideal for runs that require personalization or dynamic data. Variable printing lets businesses add barcodes, QR codes and even individualized messages directly onto their labels.

Pressure-sensitive labels are ubiquitous, found on nearly every type of product across a multitude of

industries. Their adaptability makes them a preferred labeling solution for various packaging needs.

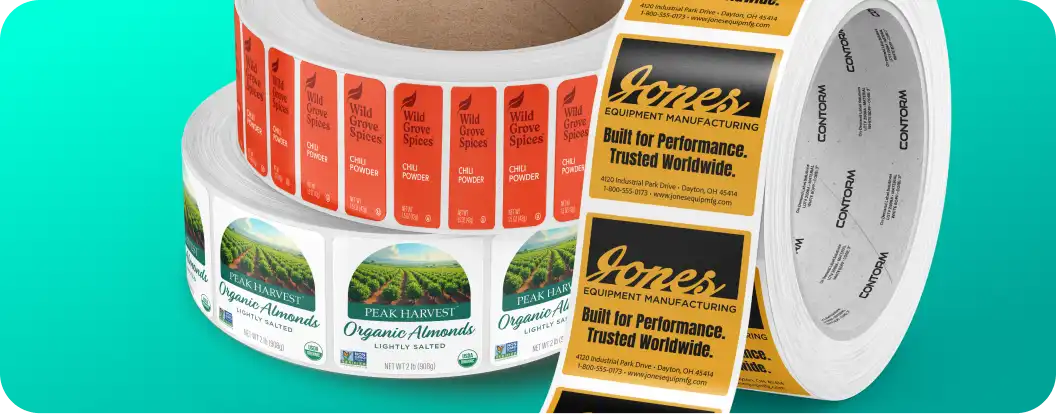

Custom wine labels utilize pressure-sensitive technology for their premium look and feel. They can withstand moisture and refrigeration, maintaining their aesthetic appeal. High-quality paper stocks, textured finishes, and metallic foil accents are commonly used.

The adaptability of pressure-sensitive labels means they can conform to bottles, cans, cartons, pouches, and jars of virtually any shape or size, making them perfect for the array of different containers used for food packaging.

In addition to wine labels, pressure-sensitive labels can be used for all types of beverages. With their durability and resistance to temperature changes, pressure-sensitive labels reliably display information and offer opportunities for custom branding and 360-degree marketing.

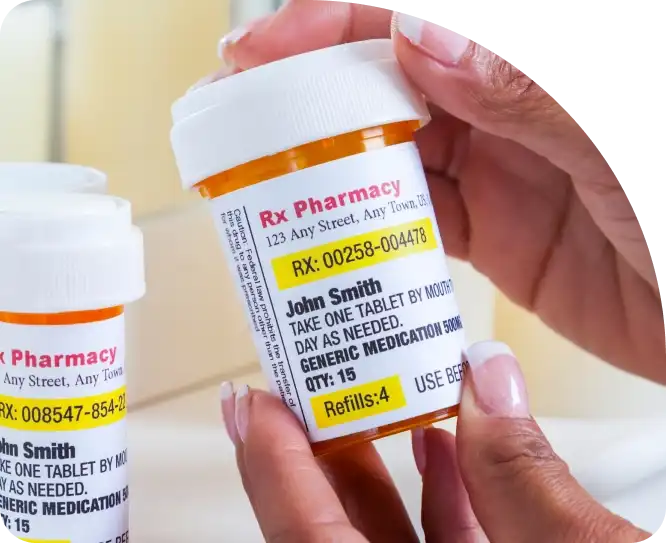

Pressure-sensitive labels deliver extreme precision, durability and adherence to strict regulatory guidelines. They can feature small, legible text, tamper-evident properties, and specific adhesives to ensure critical information remains intact and accessible for patient safety and compliance.

Pressure-sensitive labels can adhere securely to containers used for nutraceuticals, including plastic, glass, pouches, and aluminum or flexible tubes. They ensure branding, usage instructions, ingredient lists and regulatory information remain clear and legible through frequent handling.

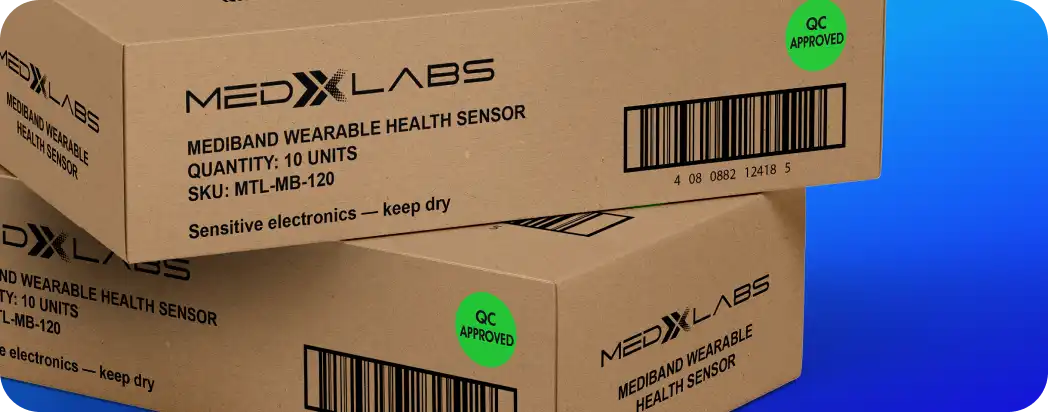

Pressure-sensitive labeling solutions provide essential identification, tracking and safety information for equipment, machinery, raw materials, and finished products while withstanding exposure to chemicals, abrasive handling, extreme temperatures and moisture.

Automotive parts and components use pressure-sensitive labels to reliably provide identification, traceability and compliance without compromising readability or adhesion while being exposed to oils, chemicals, extreme temperatures and mechanical abrasion.

Pressure-sensitive labels are an important piece in the packaging and branding of consumer goods. They have the ability to reliably adhere to surfaces like plastic, glass, metal and paperboard, ensuring product identification, traceability and an enhanced customer experience in a competitive retail industry.

The pressure-sensitive labeling industry is continuously evolving, driven by technological

advancements and shifting market demands.

Ongoing research leads to new 'label material' formulations that offer enhanced durability, improved printability, and novel sensory experiences. Similarly, 'adhesive' technologies are advancing, providing stronger bonds, easier removability for specific applications, and performance in extreme conditions, while also exploring eco-friendly alternatives.

A significant trend is the push towards more sustainable labeling. This includes using recycled content in face stocks and liners, developing biodegradable or compostable label materials, and implementing wash-off adhesives that facilitate container recycling. Brands are increasingly seeking solutions that align with their environmental commitments.

The future of pressure-sensitive labels likely includes greater integration with smart technologies, such as RFID or NFC chips for enhanced traceability and consumer engagement. There will also be continued innovation in high-speed label application equipment and more efficient, environmentally conscious printing processes.

As environmental consciousness grows, the demand for sustainable packaging solutions, including labels,

is on the rise. Eco-friendly options for pressure-sensitive labels are designed to minimize environmental

impact throughout their lifecycle. These options include:

Use water as the primary solvent, lowering VOC emissions and reducing environmental impact.

Made from post-consumer waste paper or film to lessen reliance on virgin resources.

Sourced from responsibly managed forests to support sustainable forestry practices.

Designed to break down under specific conditions, helping reduce landfill waste.

Formulated to separate cleanly during washing, enabling easier container recycling.

Use less material by reducing liner thickness, lowering waste in production.

Optimized printing and die-cutting processes help minimize scrap.

Adds space for messaging by printing on the adhesive side, reducing extra materials.

Taylor’s comprehensive pressure-sensitive labeling services guide you through every step of the label

creation process, ensuring a high-quality solution that perfectly meets your product needs.

Working with you to understand your specific label needs, brand identity, and application requirements, then assisting in the label design to maximize visual impact and functionality.

Recommending the optimal label material (face stock) and adhesive layer from a wide range of options to ensure compatibility with your product, packaging and environmental conditions.

Utilizing state-of-the-art flexographic printing and digital printing technologies to achieve vibrant colors, sharp images and consistent quality for your custom labels. We offer a variety of ink types and finishes.

Implementing rigorous quality checks throughout the production process to ensure every label meets the highest standards.

Providing various finishing options like varnishes, laminates, foil stamping, embossing and precise die-cutting to create unique shapes and enhance the tactile and visual appeal of your product labels.

.png)

Taylor delivers durable HVAC labels, nameplates, warning labels, and kits with regulatory compliance plus U.S./Mexico production, manuals, and tech do...

Discover how Taylor’s Pulse Tap and RFID labeling enabled fast, cost‑effective Google Reviews collection across offices for a tax preparation company.

Taylor delivers durable, compliant manufacturing labels powered by materials science, agency compliance, and JIT efficiency.

Discover how RFID smart packaging growth is driven by emerging applications for smart security labels, smart retail labels and RFID tracking stickers.

UL certification details and the CSA certification process guide the sourcing of labels for UL certified, cUL certified and CSA certified products.

.jpg)

RFID technology has spawned countless innovative RFID logistics solutions as industries realize the benefits of RFID in supply chain management.

Roll-fed labels and pressure-sensitive labels are both popular labeling solutions but each offers distinct advantages.

RFID labeling and packaging are in high demand as the Walmart RFID Mandate changes the landscape for retailers and manufacturers.

The durability of thermal transfer printed labels makes them the ideal thermal labeling technology for asset tags, product labels, lab labels and more

Direct thermal labels are synonymous with thermal printer shipping labels but restrictions on phenols such as BPA and BPS are changing the marketplace

Taylor’s rapid labeling solutions and MAP3 principles helped an HVAC manufacturer avoid a costly shutdown and secure ongoing production.

Taylor's rapid response and durable labeling solutions saved an HVAC manufacturer from a costly production shutdown and revenue loss.

A pressure-sensitive sticker refers to a label, decal or adhesive tag that adheres to a surface when pressure is applied, eliminating the need for heat, water or solvents during the application process. These stickers feature a specialized adhesive that creates an immediate bond with surfaces such as glass, plastic, metal, cardboard and more, making them extremely versatile for various packaging and branding options. Pressure-sensitive stickers are widely used in industries where reliable adhesion and consistent product identification are required. These stickers can also be customized with different materials, coatings and finishes to match specific durability, aesthetic or regulatory needs.

Pressure-sensitive labels are self-adhesive labels that stick to a surface with a simple press, using an adhesive layer that doesn't require water, heat or solvent to activate. They consist of a face material, an adhesive and a release liner, and are commonly found on product like food and beverage containers, packaging, and medical supplies. Their popularity is due to their versatility, durability and ease of application, whether by machine or manually.

In the labeling industry, the terms "self-adhesive labels" and "pressure-sensitive labels" are often used interchangeably, but there is an important distinction worth noting.

Pressure-sensitive labels adhere to surfaces when pressure is applied; there is no need for heat, water or solvents to activate the adhesive during label application. Adhesion occurs simply by pressing the label onto a surface.

Self-adhesive labeling, on the other hand, is a broader term that refers to any label with a pre-applied adhesive. This includes pressure-sensitive labeling but also may refer to other adhesive types. For example, heat-activated labels have an adhesive that requires a heat source to bond to a surface. Likewise, moisture-activated labels (such as old-fashioned postage stamps) have an adhesive that activates with water.

So, while all pressure-sensitive labels are self-adhesive labels, not all self-adhesive labels are pressure-sensitive labels.

Pressure-sensitive labels are available in a wide variety of types to accommodate a diverse set of packaging and product identification needs across industries. Common types include prime labels, which are used as primary branding or product labels on retail goods, and secondary labels, such as barcodes or instructional stickers that supply additional information. Specialty options also exist, like tamper-evident labels for security, expanded content labels for regulatory or multilingual needs, and promotional labels that incorporate removable coupons or instant redeemable offers. Additionally, pressure-sensitive labels are used for food traceability, produce identification (PID) and price look-up (PLU) applications, each tailored for performance on specific surfaces or environmental conditions. Businesses can choose from an array of pressure-sensitive label types, each engineered to optimize durability, efficiency, compliance and shelf appeal based on their unique requirements.

Pressure-sensitive labels are constructed from a combination of carefully chosen materials, each selected to optimize the label’s performance and appearance for its intended application. The key components include the facestock, adhesive and liner.

Selecting the right adhesive for different surfaces requires careful consideration of both the application environment and the material of the packaging or product. To ensure adhesion, businesses must evaluate factors such as surface energy, texture, cleanliness and the presence of coatings or contaminants.

Digital printing and flexographic printing offer distinct advantages depending on your label requirements, production volumes and desired customization. Selecting between digital and flexographic printing depends on factors such as run size, project complexity, the need for variable data and material preferences, ensuring that your pressure-sensitive labels achieve both optimal performance and brand impact.

Yes, sustainable options are increasingly available for pressure-sensitive labels, enabling businesses to align their packaging with modern environmental standards. Businesses can meet regulatory requirements and strengthen brand reputation by selecting pressure sensitive label solutions that support sustainability initiatives.

Absolutely. Ensuring your pressure-sensitive labels comply with FDA and other industry-specific regulations is an essential part of the label development process. Regulatory requirements can vary significantly depending on the product type and sector, and be governed by distinct rules regarding content, materials, and labeling information.

Taylor’s team has deep expertise in navigating these complex standards, including those related to ingredient disclosures, allergen warnings, barcoding, tamper-evidence and traceability. We work closely with you to understand the unique regulatory demands of your market and utilize compliant materials, inks and adhesives that meet critical criteria such as food contact safety, chemical resistance and legibility. Rigorous quality assurance practices and ongoing monitoring of regulatory changes help ensure your pressure-sensitive labels are always up to date.

You can have confidence that your labeling solution not only communicates your brand effectively, but also supports legal compliance and consumer safety.

To incorporate features such as barcodes, QR codes or tamper-evident elements into your pressure-sensitive labels, it is crucial to start with precise label design and material selection that suit both the functional and compliance needs of your application.

Additional label enhancements, such as holographic foils, microtext and security inks, can further boost authenticity and safeguard brand integrity.

Fields marked with an asterisk (*) are required.