This is the third installment of our five-part series called Labels 101: Five Key Elements of Effective Labels.

Label Liners: Often overlooked but crucial to success

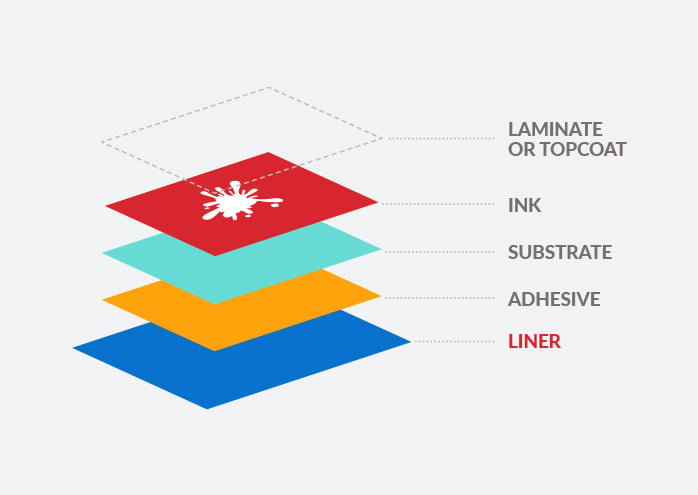

A liner is the paper or film backing that protects the adhesive on the label until it is ready to be applied. While that sounds simple enough, the wrong liner can create lost time, production delays, wasted material and even a failure of adhesion once your label is on the job.

How will your labels be applied?

A key question when selecting a liner is how the label will be applied — by hand or machine.

- Hand-applied labels require a liner that will lay flat without curling yet allow easy manual release, often through a slit back for larger-sized cut sheet labels.

- Machine-dispensed/applied labels are available in two basic types of liners: roll or fan-fold. In either configuration, the demand is for a strong, dimensionally stable liner that will feed smoothly through the auto-dispensing/application equipment without misfeeds, jams or tears.

Liners that do not release easily can lead to poorly applied labels. They also increase the chance of contaminants reaching the adhesive. Both escalate the risk of adhesion failure.

Paper or film?

Once you know how your labels will be applied, choosing the right liner material becomes a simpler decision. Here are the basic properties of each liner type:

- Paper is the most commonly used liner material because it’s usually lower in cost than film. Paper liners typically use a supercalendered (a paper-making process to smooth the paper surface) sheet. The paper is coated with silicone to keep the adhesive from sticking to the liner. Overall, paper is less consistent in thickness than film and can sometimes fracture when die cut. Paper liners are available in a variety of weights, calipers and colors.

- Film liners are more consistent in thickness than paper and more resistant to tearing. This enables more forgiving die cuts and can often avoid feeding jams in machine-dispensed applications. Film is not as reactive to humidity, ensuring less curl and better dispensing at high speeds. Film liners can be opaque or clear and are available in a wide range of weights and calipers.

The right choice between paper and film will depend on your type of adhesive, dispensing method, budget and label size. Consult with your label supplier for the optimal choice.

Personalization and liner printing

There are many important considerations when choosing a liner. Will your label require additional printing with a laser, ink jet or other printer? Labels going through a cut sheet printer must lay flat, feed smoothly and be heat-resistant in the case of laser printers. Continuous roll or fan-fold printers have specific liner requirements. Printing on the back of the liner requires the liner surface to be receptive to ink.

Your application process is critical

No matter the type of liner, how the liner is removed and the label applied is crucial in avoiding a loss of adhesion. The application process should avoid clothing fibers, dust, other particles, skin oils, moisture and chemicals from coming into contact with the label’s adhesive. This requires a consistent and regimented label dispensing methods. A qualified label supplier can suggest ways to improve your application process.

Eco-friendly options

Since the liner requires disposal once the label is applied, choosing a biodegradable liner can be an important consideration. Fortunately, many types of paper and film liners fit the bill. Some liners can be recycled, but you need to contact your local recycler to confirm that they will accept it. Moreover, some linerless label options exist. Ask your label supplier for specific recommendations and samples.

Making the right choice

Choosing the right liner means your labels will arrive in good condition and be applied correctly with the adhesive intact. The wrong choice of liner can lead to wasted dollars, lost time and even a loss of adhesion, creating costly failures. Yet, the liner is just one part of the formula for creating the right label.

To learn more about the other key components of an effective label, read these posts in our “Labels 101” series:

- Choosing the Right Substrate

- Choosing the Right Adhesive

- Choosing the Right Ink

- Choosing the Right Laminate

For more information on how to manage your print effectively, including labels, read about PrintStack, the Operating Model for Print.