See how Taylor is working to improve sustainability in label manufacturing both before production starts and after the label has been used.

Grow your business and raise your ROI by improving label performance and reducing total costs. Our experts collaborate with you to identify the specific requirements of each label needed and determine the best choice for your products.

Work with one of the world’s leading label suppliers to raise brand awareness and build trust

through your printed product labels.

The right material specifications to meet the demands of each label application.

Demand forecasting systems to meet seasonal demand and avoid line-down situations.

Industry-leading printing technology for shorter lead times and quick design changes.

UL, cUL, CSA and ANSI expertise to ensure your label designs are always in compliance.

Pressure-sensitive labels adhere to surfaces when pressure is applied. They do not require heat, water or solvents to activate the adhesive.

Can be applied to many different product shapes and surfaces.

Can withstand a range of harsh conditions, such as cold or wet environments.

Generally more affordable than other label types.

Can be engineered with numerous substrates and adhesives to meet application needs.

Pressure-sensitive labels are used in a wide range of industries to convey information and enhance the look and feel of products.

Perfect for branding and packaging cosmetics, personal care items, household goods and more.

Because they can adhere to all shapes of rigid containers, they can be used for many food and beverage products, such as wine labels, spirit labels, and specialty food and beverage packaging.

Due to their durability, pressure-sensitive labels are ideal for products that must perform in indoor and outdoor environments under mechanical, chemical and weather-related rigors.

Pressure-sensitive labels are also used for automotive applications due to their resistance to fading and ability to meet exposure demands.

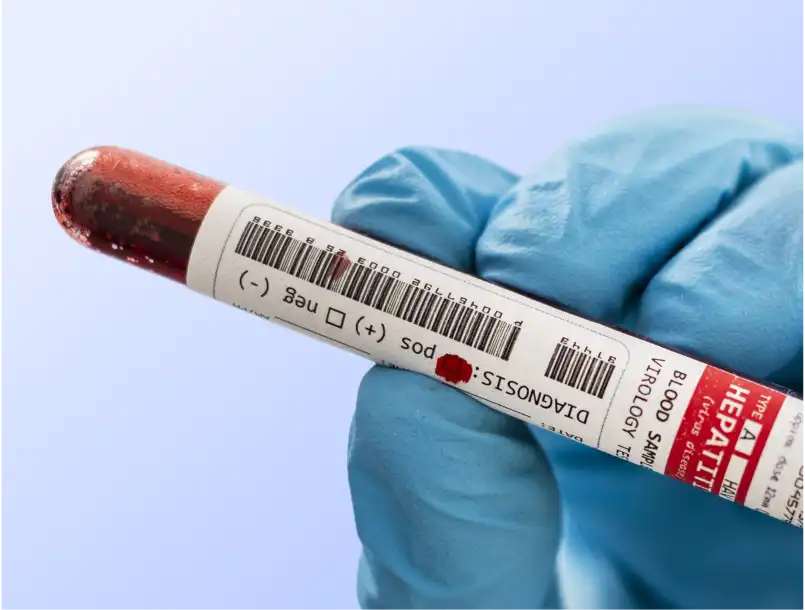

Pharmaceutical, nutraceutical and over-the-counter products that require high-performance and authentication and tamper-evident measures.

Ideal for branding and packaging agricultural goods that have to endure transport and constant handling.

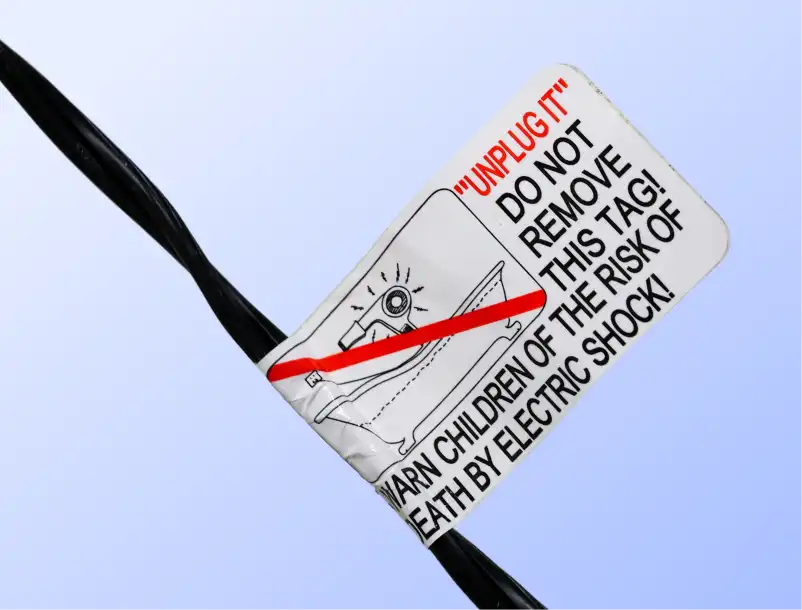

Durable labels are designed to withstand frequent handling and exposure to elements such as heat, moisture, heat, UV rays, chemicals, mechanical wear and tear, and adverse weather.

Perform under all types of conditions, and are resistant to solvents, heat, scratches and more.

Maintain their integrity and readability over time without tearing, fading or peeling.

Can support smart label technology such as QR codes, NFC, RFID and barcodes.

Found nearly everywhere in every industry, from electrical devices to lawnmowers and cars.

Ultimately make products safer and more effective when used by the end consumer by reliably displaying important information.

Durable labels are engineered to ensure critical information is clearly displayed while enduring harsh conditions brought about by use in

many types of industries.

These labels can withstand high temperatures, chemicals, and abrasion, ensuring that important information remains legible on machinery, equipment and components in industrial settings.

Durable labels are essential for labeling medical devices, equipment and supplies that are subject to frequent cleaning, sterilization and exposure to various chemicals.

Automotive parts, components and assemblies need labels that provide reliable identification and tracking while resisting oil, grease and extreme temperatures.

Durable labels are required for electronic products such as components, circuit boards and devices whose labels must clearly display information through exposure to heat and abrasion.

Products and equipment that have to endure outdoor conditions use durable labels to withstand UV exposure, moisture and a wide range of temperatures.

Heavy-duty drums and chemical containers storing hazardous materials must be clearly labeled and these labels must resist handling, moisture and temperature changes.

Shrink sleeves are printed labels that can conform to nearly any size or shape of container through a heated application process.

Full-body coverage with 360-degree branding and a seamless fit with no visible gaps.

Can handle moisture and abrasion, and can include perforations and tamper-evident options to protect the contents.

Eliminate the need for custom-printed containers, making them a budget-friendly option.

Can be customized as full-body sleeves, tamper-evident bands, neck bands and multipacks.

Removable shrink sleeves feature a "zipper" down the side with tiny perforations, allowing users to easily peel the sleeve off the container and recycle the blank container.

Shrink sleeves are prominently for consumer packaged goods in multiple industries and settings.

Since they can conform to nearly any size or shape, shrink sleeves are able to provide full-body coverage for products that come in bottles, cans, jars and tubes.

Shrink sleeves can be made from light-blocking films, making them ideal for grocery items, produce and other products that must maintain their freshness for long periods of time.

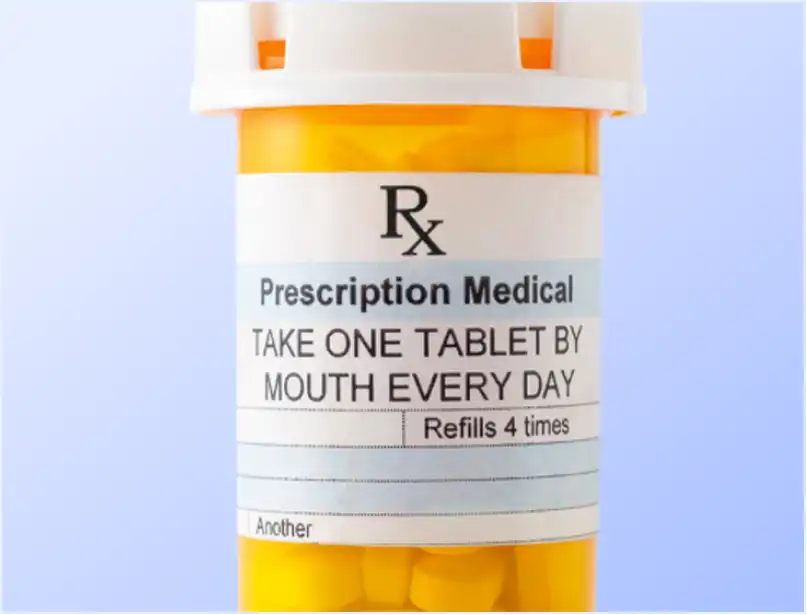

Shrink sleeves are a perfect fit for pharmaceutical, nutraceutical and over-the-counter products that come in a variety of container shapes and require space for both branding and ingredient listings.

With unique shapes and designs that need to display important details, pet products are a great match for shrink sleeve labeling.

Shrink sleeves are perfect for branding, protecting and informing about creams, gels, cosmetics, and other health and beauty products.

Shrink sleeves can be used to group sets of products, band multiple products together for bulk orders and offer product samples alongside other purchases.

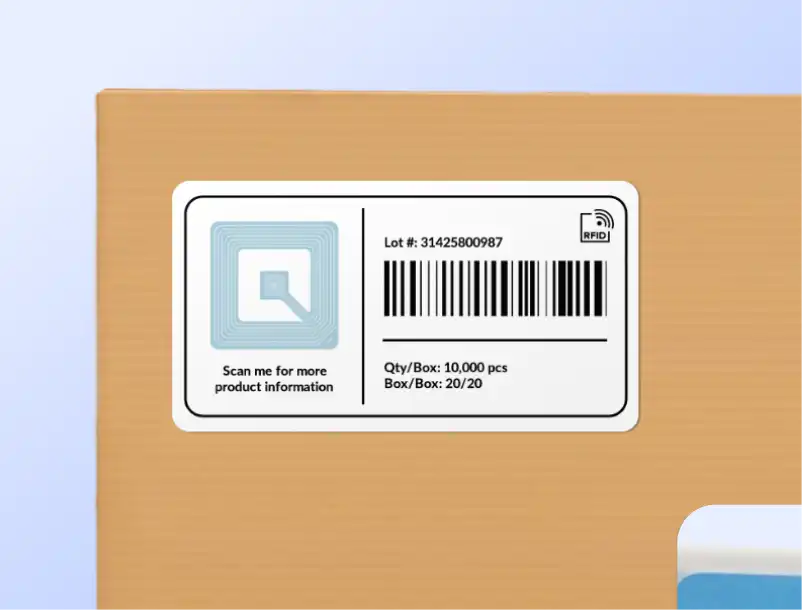

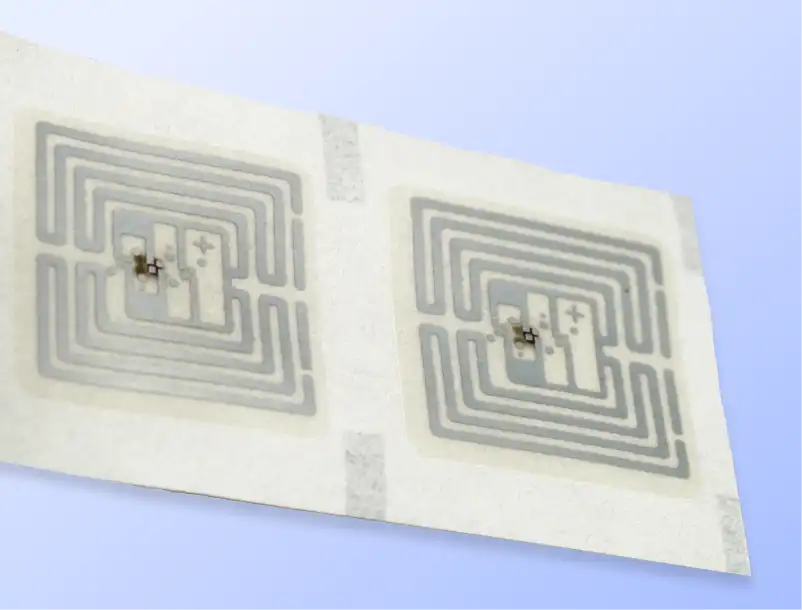

Radio frequency identification (RFID) labels, also known as RFID tags, use radio frequency identification technology to store and communicate information. Smart labels are labels that incorporate digital technology, including RFID tags, NFC chips and QR codes.

Enable the real-time tracking of assets and products in transit and monitoring of inventory levels.

Forecast demand more accurately, maintain optimal stock levels and reduce the risk of out-of-stock situations.

Many retailers and organizations require suppliers to use RFID labels to ensure compatibility with their tracking systems.

Simplify inventory audits by automatically logging movements and usage of assets, reducing the risk of misplaced or lost items..

Automated processes such as real-time inventory tracking, simplified asset monitoring, and rapid data collection eliminate the need for manual entry and repetitive barcode scanning.

RFID and other smart labels can serve a variety of purposes and streamline processes in many different industries.

RFID technology can be used to create interactive consumer engagement such as personalized marketing and product information access.

RFID solutions allow the tracking of assets such as machinery, tools and medical equipment throughout the supply chain.

Many automotive labels include RFID features that support compliance, quality control and traceability while resisting fading and damage.

With RFID solutions, businesses can reduce loss and improve inventory management while ensuring products reach their destinations.

RFID technology can improve patient safety and care by providing real-time tracking of patients, staff and equipment in healthcare facilities.

RFID labeling enhances customer safety and experience by tracking the freshness, origin and history of grocery and produce items.

RFID label solutions can provide consumers with instant access to product details, authenticity verification and even interactive experiences.

Thermal labels fall into two categories: thermal transfer and direct thermal labels. Direct thermal labels use a heat-sensitive material rather than a thermal ribbon, and will fade with time. Thermal transfer labels do use a thermal ribbon, which is melted and transferred to the label surface during the application process to create permanent images that will not fade. Both labels provide important but distinct benefits to the user.

Both can adhere to a wide range of products, shapes and containers.

Direct thermal labels are budget-friendly, as they require no ink, toner or ribbons, making them easy to maintain.

Create permanent images that will not fade, making them perfect for products whose labels must last for long periods of time.

Direct thermal labels have one part compared to two for thermal transfer labels. This requires fewer label SKUs to be procured, shipped, tracked and stored.

Many industries use either or both direct thermal and thermal transfer labels for their products and services.

The durable, long-lasting images created by thermal transfer labels make them ideal for tracking parts and products through stages of production.

Thermal transfer labels are perfect for tools, equipment and machinery that must clearly display information and instructions for long periods of time.

Thermal transfer labels are used for patient identification, laboratory, medication and specimen labeling, and medical device tracking that must maintain readability and scannability for long periods.

Thermal transfer labels are used for parts labeling and tracking. They withstand harsh conditions and provide long-lasting identification.

Direct thermal labels offer quick and efficient printing for price tags, shelf labels and receipts, making them a great choice for fast-paced retail environments.

Direct thermal labels are used for short-term needs such as shipping labels and inventory management. Thermal transfer labels are used for product labeling to withstand various environmental conditions.

Direct thermal labels are perfect for shipping labels and tracking as they are cost-effective and require minimal maintenance.

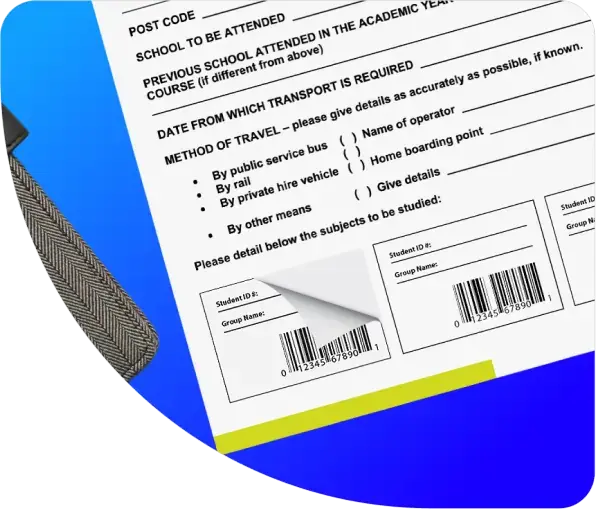

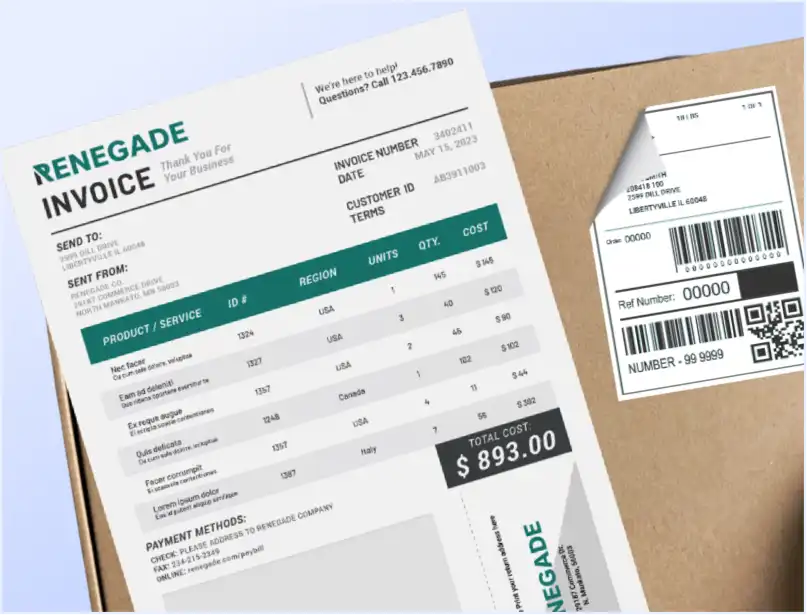

Integrated labels simplify complex processes by merging related documents into one single unit. They can be the combination of a form and a label or two labels of different materials.

Combining label components saves money by decreasing inventory needs and obsolescence.

Simplify processes by removing extra printing steps, which in turn improves accuracy and reduces the number of SKUs to order and track, and reduces order-processing time.

Printing all information in one step eliminates mismatched and missing documents, simplifies data entry, and reduces the chance for errors.

Many industries can rely on integrated labels to clearly and reliably convey information while simplifying the labeling process.

Integrated form and label constructions are perfect for build sheets, packing slips, product labels, warranties, serial numbers and for triggering daily production runs.

Integrated label combinations are ideal for multi-part and multi-color prescription labels and other documentation used in pharmacy settings.

Integrated labels can enhance a product’s presence on the shelf and streamline shipping and delivery.

Form and label combinations are often used for integrated packing slips and shipping labels, improving efficiency in logistics.

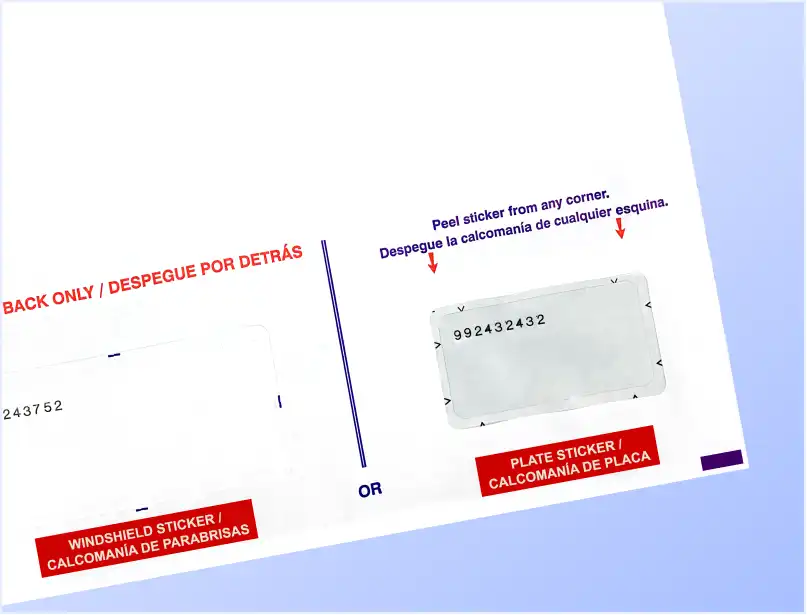

Integrated labels ensure compliance and simplify the printing and use of automobile licenses and parking permits.

In-mold labeling (IML) is a manufacturing process where a pre-printed label is placed in a mold before the plastic part is formed, resulting in a durable, integrated label that becomes part of the finished product.

In-mold labels are used to enhance the appearance and longevity of decorative labels on many consumer products.

IML offers permanence, durability and improved graphics over heat transfer/pad printing or screen printing.

Deliver superior graphics, communicate important product features or instructions and withstand the test of time.

IML withstands heavy use and extreme environments and ensures labels are clear and readable throughout the life of the product.

In-mold labeling can be applied to products and items in a wide range of industries, with everything from decorative components to

permanent instructional labels.

Can be used for cosmetics, personal care items, luxury goods, household products and more for full-color graphics while ensuring visuals and information stand up to frequent handling.

IML is used for interior graphics to maintain a high-quality appearance while withstanding everyday use, and for exteriors, such as bumpers and mirrors, that are exposed to the elements.

In-mold labels are especially suited for heavy machinery and equipment, as they endure harsh conditions that traditional labels might not survive while keeping safety and operational information intact and legible.

Many electronic products, such as remote controls, smartphones and kitchen appliances, utilize IML to incorporate labels directly into their casings to ensure product information remains legible.

In-mold labels are a great option for chemical drums, containers and industrial vats that hold hazardous materials and products and need to clearly display information in harsh conditions.

Roll-fed labels are a type of labeling solution where the labels are provided on a continuous roll. These labels are typically fed through a label applicator or a printing system, where they are precisely positioned and applied to products or packaging materials. Roll-fed labels offer numerous advantages to many industries, making them a favorable choice for high-speed production environments.

Allow for seamless and automated application processes.

The use of roll-fed labels and speed up production times crucial for companies working under tight deadlines.

Can be adapted to suit a variety of substrates, making them compatible with different product types while meeting various industry requirements.

These labels are perfectly suited to combine both detailed branding elements with compliance information.

Because of their ability to accelerate production time and customizable properties, roll-fed labels are ideal for many applications across a

wide range of industries.

These labels cater to packaging formats commonly seen in grocery stores, such as bags, boxes or tubs, ensuring that product information is applied quickly and consistently.

Roll-fed labels are a great option for beverages of all types, providing high levels of customization and consistent branding for different sizes of bottles and cans.

Roll-fed labels can be applied quickly and accurately to products like cleaning supplies, kitchen aids and storage solutions to maintain a consistent brand appearance.

Roll-fed labels can be extensively customized for critical information such as dosage instructions, regulatory data and safety warnings to healthcare providers and patients alike.

Can conform to various packaging formats, ranging from sleek bottles to compact jars and tubes, ensuring consistent brand identity across product lines.

These labels be used for pet products such as food bags, treat packages and grooming product containers to display displaying information including ingredients, instructions and nutritional benefits.

These labels are pre-printed, readily available, and often come in a range of standard sizes and formats, making them an ideal choice for companies looking to maintain a consistent and efficient labeling process without the need for customization.

Stock labels help businesses save time and reduce costs associated with complex printing processes.

Versatile and can be used for a multitude of purposes, such as barcode labeling, shipping labels, inventory tags and more.

Ensure a level of standardization that supports seamless integration across different operational areas, boosting product identification and information dissemination.

Businesses that require fast turnaround times benefit significantly from the ease of stock label procurement, as they allow for immediate deployment, streamlining day-to-day operations.

Stock labels are widely used by various industries that require immediate labeling solutions due to their pre-printed nature and ease of use.

These labels find extensive applications in inventory management, serving as invaluable tools for tracking and categorizing different items.

Stock labels streamline the shipping and receiving process by providing clear, consistent labeling for packages and goods as they move through distribution channels.

Create shipping labels and price tags for quick deployment in fast-paced retail settings. They are particularly beneficial during promotional periods or busy seasons.

Stock labels are perfect for barcode labeling as they can be seamlessly integrated into existing electronic inventory systems.

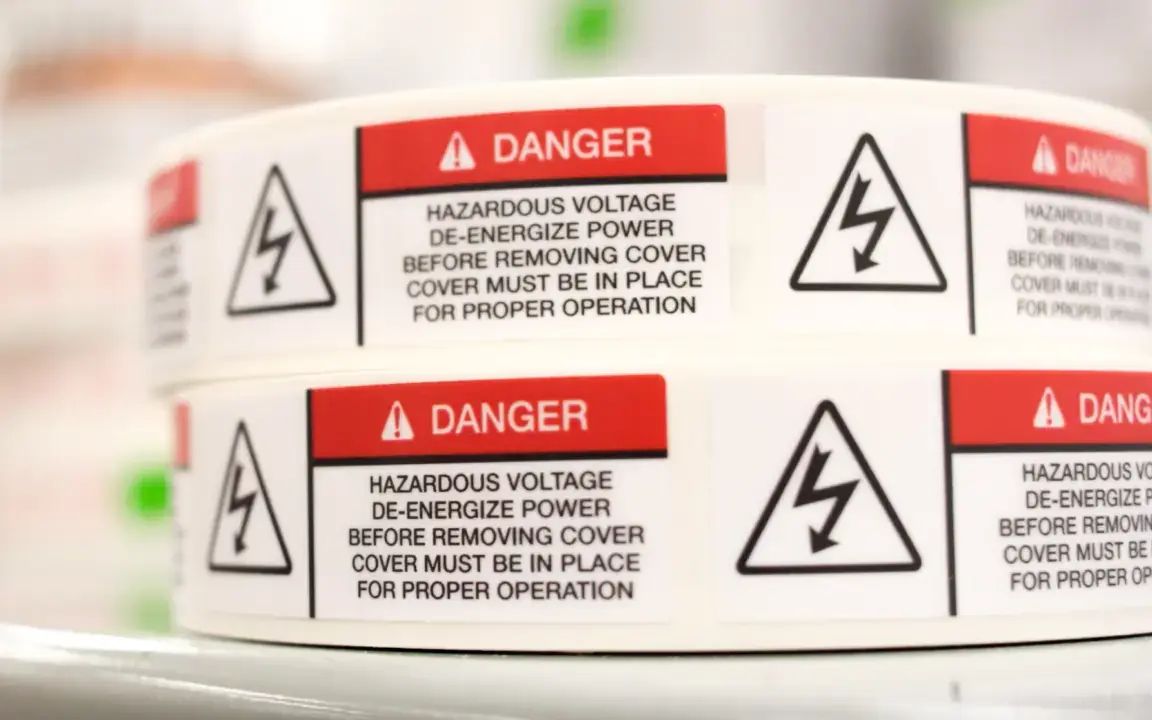

Security labels are uniquely designed to deter tampering, counterfeiting, and unauthorized access, making them essential for maintaining product integrity and consumer trust.

Adapt to the specific needs of different sectors through the incorporation of tamper-evident designs, holograms, and serialized numbering.

By providing visible evidence of tampering or unauthorized access, security labels are a great aid in preventing product theft and loss.

Allows them to be used for various products to ensure brand protection and regulatory compliance, including electronics, automotive and luxury goods.

Streamline operations and reduce manual errors by automating security checks through serialization and embedded technologies.

To protect against counterfeiting and ensure product integrity, security labels use technologies such as holograms, QR codes and RFID tags to provide products with a unique identity.

Security labels are a vital component in various industries, providing protection and assurance to customers regarding products and

information.

Play an important role in shipping and receiving industries by ensuring the safe and secure transport of goods through solutions that enhance both protection and efficiency.

The healthcare industry uses security labels for protecting patients from counterfeit or compromised prescriptions or products and ensuring the authenticity of medications.

Using tamper-evident features and unique serial numbers, secure labels ensure that packages remain sealed and untouched during transit, providing visual evidence of any unauthorized access.

Can be used to indicate that a room has been thoroughly cleaned and sanitized, and act as a tamper-evident measure to alert both hotel staff and guests in case of any unauthorized entry.

Rental car services affix security labels to fuel caps, trunks, or door seams immediately indicate unauthorized access or attempts to damage a vehicle.

Labels are key to brand recognition, product info and compliance, and must be built to endure diverse conditions across industries.

Food and beverage labels must be visually appealing and inform consumers about ingredients, nutritional facts, allergens and expiration dates.

For produce and grocery items, labels need to adhere to irregular surfaces and use variable data printing for identification and pricing.

Personal care products, including cosmetics, skincare and toiletries, rely on labels to reflect brand luxury and communicate usage instructions and ingredients.

Labels for household products and pet supplies must be durable and provide clear instructions for use and safety warnings.

Barcode labels are used across all industries, and are essential for efficient inventory management, point-of-sale systems and supply chain logistics.

Nameplates are durable labels typically made from metal or rigid plastics, and are used for permanent identification of products, machinery or equipment.

Custom stickers offer engaging and versatile label solutions, including die-cut promotional stickers and product seals for branding, promotion and unique applications.

Critical for safety, asset management and operational efficiency. Industrial labels must be exceptionally durable to withstand extreme conditions, including chemicals, abrasion, temperature fluctuations and harsh weather.

Safety and compliance labels improve workplace safety and reduce accidents by providing crucial warnings, instructions and regulatory information on machinery, equipment and hazardous materials.

Asset labels, such as barcode labels or smart labels (RFID), are made from highly durable materials to ensure longevity in the tracking and managing of company assets, tools and equipment.

Barcode labels are fundamental for tracking work-in-progress, managing raw materials and identifying finished goods, improving efficiency and accuracy within the supply chain and manufacturing processes.

Industrial nameplates are engineered to permanently mark machinery, control panels and other industrial components with critical operational data, serial numbers and safety warnings.

The backbone of smooth operations from warehouse to storefront through the streamlining of supply chain management, inventory control and customer-facing information.

Shelf labels provide product names, pricing and promotional information directly to consumers at the point of sale.

Warehousing and distribution labels track the movement of products within storage facilities and are engineered to perform demanding environments throughout the supply chain.

Shipping labels contain all the information needed for the accurate and efficient delivery of products, including sender and recipient addresses, tracking numbers, barcode labels, and more.

Price tags are retail labels that display the cost of items, and can be produced as simple adhesive labels or hang tags.

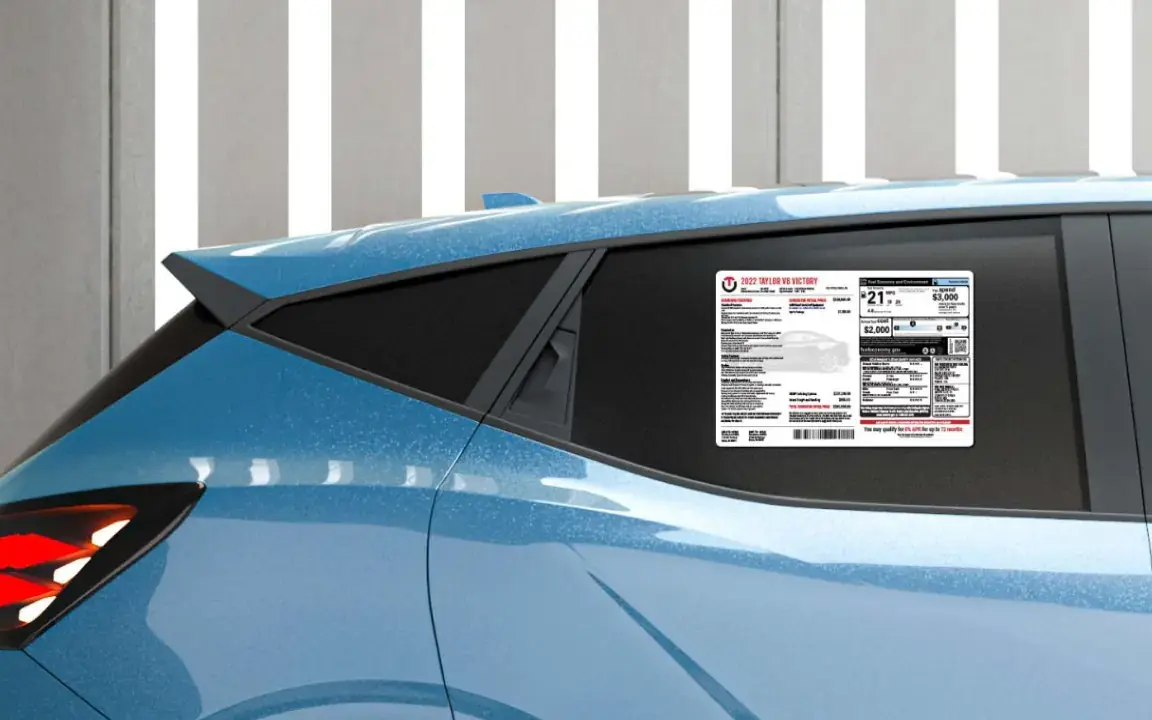

Automotive labels face some of the most challenging conditions, requiring exceptional durability, resistance to chemicals, and adherence to strict performance and safety standards for both interior and exterior labels.

Monroney labels are legally mandated and highly regulated window stickers for new automobiles in the U.S., detailing fuel economy, pricing, options and safety ratings.

Parking labels include permits, hang tags and windshield decals that require strong adhesion and weather resistance to stay legible and securely attached for extended periods of time.

These labels are designed for under-hood, engine and interior applications and must withstand extreme temperatures, oils, fuels, abrasions and cleaning agents while maintaining legibility and adhesion.

Vehicle registration labels, such as license plate stickers, must be highly durable and tamper-evident, and maintain their clarity and adhesion enduring various weather conditions.

Conspicuity tape is a highly reflective labeling material applied to the sides and rear of large vehicles to enhance visibility and safety, especially at night or in low-light conditions.

In the healthcare industry, labels play a critical role in patient safety, medication management and laboratory processes where they must always maintain accuracy, clarity and sterility.

Patient ID labels and wristbands provide immediate identification for patients, with scannable barcodes linking them to their medical records, medications and treatments.

Pharmacy labels ensure correct medication administration by providing essential information on prescription bottles, including patient names, medication names, dosages, instructions and warnings.

Laboratory labels are used on blood tubes, specimen containers and other lab samples, and must withstand extreme temperatures, chemicals and handling, while maintaining data for accurate tracking.

Visitor labels are temporary identification solutions for guests in hospitals and clinics, enhancing security and easy identification within healthcare facilities.

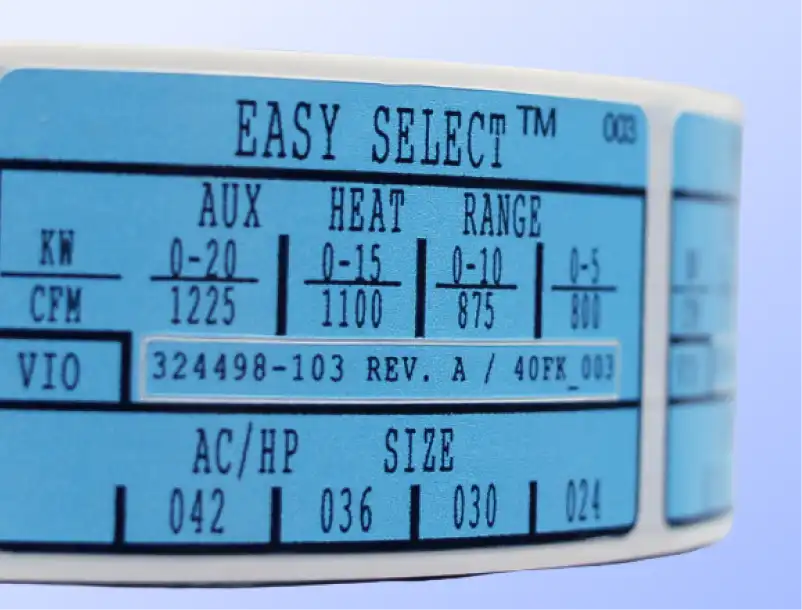

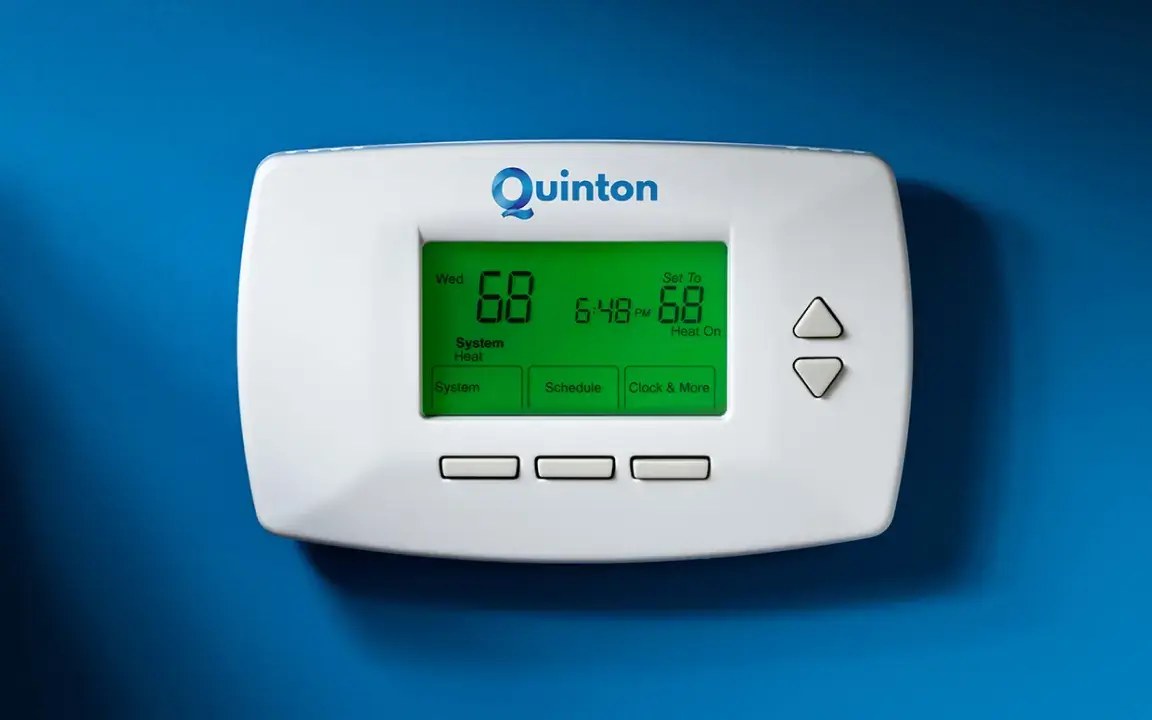

Specifically designed for heating, ventilation and air conditioning systems, HVAC and similar labels are critical for both avoiding line-down situations during production and conveying important safety and operational information.

These types of labels must endure extreme temperature fluctuations, moisture, dust and often oily environments while providing clearly legible and crucial information about maintenance, safety and system specifications.

Technical literature includes user manuals, installation instructions, warranty cards and other types of printed documents that ship with manufactured products and are vital for efficient and safe operation.

Products that use HVAC labels usually require several different types and numbers of labels to be compliant with industry regulations. Label kitting reduces the amount of SKUs needed for inventory, and ensures all labels arrive at the same time.

Equipment labels are designed to perform in demanding environments in order to identify, inform and guide the safe operation and maintenance of a wide range of machinery and appliances.

These labels provide safety warnings, operating instructions and branding for products like lawnmowers, chainsaws and generators while being resistant to harsh weather, fuel, oil and abrasion.

Agricultural labels used for farm machinery and equipment must convey vital operating and safety information while resisting damage from dirt, moisture, chemicals and prolonged sun exposure.

Medical device labels providing detailed information on device specifications, usage, sterilization instructions and traceability while remaining in compliance with regulatory requirements.

Appliance labels provide essential information such as serial numbers, energy efficiency ratings and safety warnings for household and commercial appliances.

With In-mold labeling (IML), the label is permanently bonded to the plastic part, ensuring equipment labels remain clear and readable while withstanding heavy use and extreme environments.

We offer sustainable raw materials that make your labels more environmentally friendly, and continually invest in recyclable

substrates and advances in digital label press technology.

Environmentally friendly label printing involves using materials that reduce waste, conserve resources and are safer for the planet. Many types of label materials can increase sustainability.

Our paper substrates can be surface Linerless labels are labels that have no backing liner, significantly reducing waste. Our linerless labels eliminate 50% of normally discarded material and reduce roll change costs with rolls that are 75% longer. You’re also able to get a label cut to the exact length needed.

Thin-stock labels reduce the overall material consumption per label, leading to less waste and often lower shipping costs. Our label constructions are up to 50% thinner than conventional labels, which saves on printer changeovers, landfill waste, storage requirements and transportation costs.

Standard shelf labels can be made more eco-friendly by utilizing recycled materials or thinner stocks. We use ultra-thin, non-vinyl polyester that contains up to 30% post-industrial content. The 1.0 mil thickness reduces waste and its lighter weight saves on shipping costs.

The Forest Stewardship Council (FSC) certification ensures that label materials sourced from forests are managed responsibly, promoting sustainable forestry. Choosing FSC Certified Materials and Facilities for label printing demonstrates a commitment to environmentally conscious sourcing.

Advances in label technology provide a wide range of options to create custom labels that meet specific

application needs, from photo-quality graphics to extreme durability.

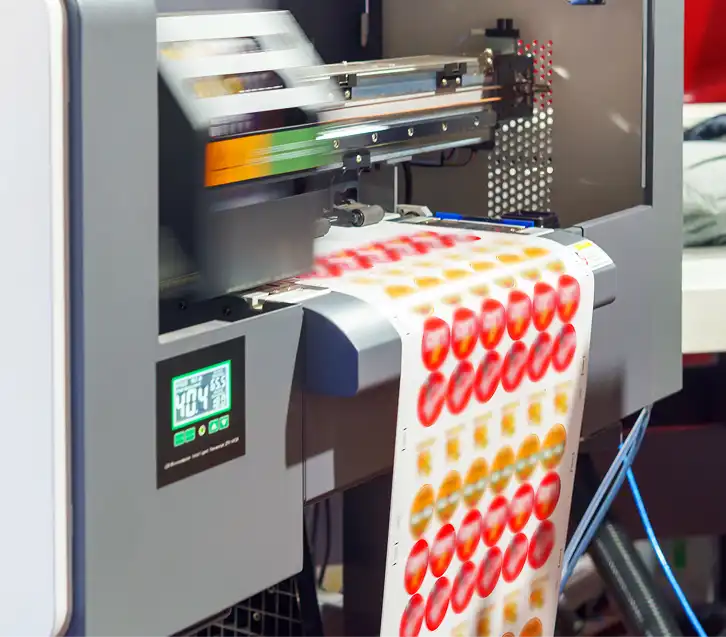

Digital printing offers incredible flexibility, enabling custom labels with variable data, short runs and faster turnaround times without the need for plates.

Combines digital printing capabilities with flexographic printing, enabling high-volume production with the flexibility for variable printing and intricate designs.

A traditional printing method known for its speed and cost-effectiveness on large orders, and is ideal for high-volume runs of items like product labels and packaging.

Allows for unique content on each label within a print run, such as barcode labels, serial numbers, QR codes and personalized information.

Produces extremely durable labels with thick, vibrant ink deposits, making it ideal for label applications that need to withstand harsh chemicals, abrasion or outdoor exposure.

Taylor’s label services are designed to streamline operations, manage inventory and ensure quality from design to application. We combine decades of experience with industry-leading technology to build labeling solutions that help you reduce costs and eliminate line-down risks

Provides readily available labels in common sizes and materials for quick fulfillment for standard applications.

When you partner with Taylor, you have access to one of the largest selections of stock labels in the industry.

Flexible packaging is highly portable. It improves the consumer experience as it allows consumers to easily carry it wherever they go, enhancing convenience and expanding market reach.

Specifically designed for laser printers, where toner powder is fused to the label surface using heat. A great choice for applications like product labeling or outdoor signage.

Uses a thermal ribbon heated by printheads to melt the ribbon material and transfer it to the label surface. Creates permanent images that will not fade.

Designed for use with inkjet printers, and coated to absorb liquid ink during the production process. For indoor applications and short-term outdoor environments.

Inventory management is a core label service from Taylor, providing you the ability to have the

right quantities of the right labels on hand, avoid overstocking while meeting spikes in demand,

reduce obsolete inventory and lower the total cost of ownership of each component.

Consolidating vendors streamlines every aspect of your labeling programs. Working with Taylor for all your labels and label-related products will save you time and money on everything from design and engineering to inventory management, version control, shipping and logistics, and more.

Data-driven demand forecasts make sure production lines never shut down. Our forecasting solutions give you the insights you need to ensure high-volume products are always available, while lowering the amount of obsolete inventory at the same time.

Taylor’s strategic warehousing distribution services ensure that your labels are stored correctly and delivered efficiently to where they are needed. Our geographically positioned distribution centers mean your labels get delivered faster and you save on shipping costs.

Taylor’s custom label kitting services allow you to print all labels related to a specific piece of equipment, machinery or product on a single sheet. Kitting means you only have to manage one SKU instead of multiple, and ensures all the right labels are applied and that none are missed.

Electronic Data Interchange (EDI) integrates label ordering and supply chain information directly between company systems, automating processes and improving accuracy and speed. Our ordering platform can integrate with your existing systems or be implemented as standalone solution.

Taylor’s label testing includes the grading of readability, adhesion, resistance to harsh environments and chemicals, and more durability tests to ensure your labels meet the requirements needed for real-world performance.

The Production Part Approval Process (PPAP) is a standardized process in manufacturing (especially automotive) that ensures a supplier can consistently produce a product that meets engineering design and specification requirements, including labels.

1st Article Approval involves inspecting the initial production samples to verify that all specifications are met before high-volume production begins. This quality control step is crucial for custom labels.

Test orders evaluate label performance in real-world conditions on a small scale before committing to large production runs, ensuring the right solution is chosen.

Durability testing assesses how labels withstand various stressors such as abrasion, chemicals, temperature extremes and UV exposure, ensuring they maintain their integrity.

Whether you need UL certified materials, ANSI design compliance, a basic compliance statement or a Full Material Disclosure, our consultants can help you through both the straightforward and complex aspects of safety, security and compliance.

ISO 9001:205 (Quality), ISO 14001:2015 (Sustainability) and AITF 16949:2016 (Automotive)

Agency compliance expertise in ANSI, UL, cUL, CSA and GHS

Members of the ANSI Z535 board

Knowledgeable and compliant in REACH, RoHS, conflict minerals and California Prop 65

SFI®/FSC® certified and we work with certified suppliers

When you partner with Taylor, a dedicated account team will be structured for your specific needs and objectives. They’ll have the assets, tools and technologies to ensure efficiency in everything from label concept to completion.

Quarterly Business ReviewsBy examining data and analytics, you'll be able to identify trends, hot products and new strategies to help you meet your marketing ROI goals.

We use this process for every client we work with. In order to maximize your savings and efficiency, our experts perform an in-depth analysis of every part of your label program.

Our experts analyze the form, fit and function of every label you use to find opportunities for material consolidation, re-engineering and substitution, die size reductions, and migration to digital. We do this in six steps:

We’ll help you identify which labels are primed to make the switch to digital, and you’ll save on costs by reducing waste, obsolescence and aging materials - and possibly the need to warehouse material at all.

Order large or small quantities with no cost impact through a streamlined process that enables both accelerated turnaround times and easy spec updates through simple drawing changes.

You can also lower your total spend by going digital. By working with our label experts to determine which labels would benefit from converting to digital production, you’ll lower your warehousing costs, and eliminate fees for tooling, ink changes and printing plates.

Our digital on-demand label program facilitates JIT delivery when you need it most. We eliminate bottlenecks and high costs associated with storage and distribution.

Label management requires a consultative and innovative approach. You’ll want a label partner with expertise in materials science and design, high-speed press technology and access to the latest in automation.

That’s the kind of partnership you’ll have with Taylor. Our research and development experts develop customized solutions to meet your needs. Whether it's a chemical application, adhesive, liner, substrate or other label component, we’ll find the right solution for you - even if we have to create it for the first time.

Taylor works with all major OEM printer manufacturers to offer a complete line of label

printers, toners, ribbons and more. For even more imaging and printer supplies, take a look at

our supplies management brochure.

See how Taylor is working to improve sustainability in label manufacturing both before production starts and after the label has been used.

We continuously invest in the latest print technologies to solve the challenges that Monroney labels can present.

Taylor’s stock label program has everything you need when you’re trying to save money or beat the clock.

Integrated labels are a Taylor specialty. See how identifying opportunities to consolidate multiple forms and labels into a single unit reduces costs and risks.

Find film options for any application and see why Taylor is an industry leader in IML.

Take a look at our healthcare wristband and label catalog. Inside you’ll find the products you need to improve patient care and reduce costs.

You don’t have to overorder to save money. Our digital durable labels program ensures you can order as needed with no cost impact.

See how your products can benefit from the use of in-mold labeling.

Reduce the costs of component parts - right down to the smallest label.

IML and IMD are used interchangeably in the labeling industry. But they are different. Knowing these differences will help you make the right labeling choice for your products.

Which labeling technology is the best? It depends on your goals. Learn about flexo and digital printing, and the third option that combines the best of both.

Learn about the top three challenges facing the world of industrial labels, and how Taylor’s production and fulfillment solutions can help you overcome them.

Realize your cost savings potential with our in-depth analysis program.

Learn what differentiates thermal transfer and direct thermal labels and what to consider when you’re making the choice between the two.

See how companies are able to reduce losses and errors while improving compliance and safety with RFID labels.

See how Monroney labels have changed over time as consumer protection has improved and automotive technology has advanced.

We understand the vital role that labels play in a production process. Our team of labeling experts works closely with clients to identify the specific performance requirements of each label and then recommends ways to improve label performance, reduce obsolescence, lower total costs and enhance operational efficiencies. Combined with our technologically advanced production network, we are able to deliver a comprehensive labeling solution that creates operational efficiencies and eliminates line-down risk.

Our highly trained team of technical consultants will analyze the fit, form and function of all printed production parts with the goal of driving cost reductions via a number of process improvements. We’ll look for opportunities for material consolidation, re-engineering and substitution as well as die size reductions and migration to technology solutions using six clearly defined stages:

It’s all part of our MAP3 process (Methodical Assessment of Printed Parts and Processes). We'll help you lower the total cost of label ownership and reduce risk by increasing compliance with industry labeling regulations.

We have a wide selection of materials, substrates and adhesives to ensure your order is produced to your exact specifications. Our state-of-the-art digital, flexo and screen printing capabilities give us the flexibility to deliver cost-effective print runs of any size or complexity.

Our on-demand digital production enables efficient, low-volume runs of highly complex label designs. Your labels won’t become obsolete in a warehouse. They’ll be produced as needed and can be easily updated through simple drawing changes.

We also offer thin and direct thermal linerless labels that help eliminate waste, reduce the number of SKUs and roll changes you need, and lower storage and distribution costs.

Absolutely. Taylor has one of the largest selections of stock labels in the industry, offering a wide array of options to meet all your needs. We provide same-day shipping for all stock orders received prior to our shipment cutoff time.

For a listing of the most common stock items, contact a sales representative or view our stock label catalog.

We realize the importance of meeting regulatory requirements in your label designs and finished items. That’s why Taylor collaborates with UL, cUL, CSA and ANSI to ensure compliance based on industry, usage and state standards.

We require all of our material vendors to update material compliance statements annually to ensure regulatory statuses are current. Additionally, we provide and offer support for REACH, RoHs, conflict minerals and California Proposition 65 for industrial label markets.

Whether you need certified materials, design compliance, a basic compliance statement or a Full Material Disclosure, we can help.

Our certifications and proficiencies include:

Certainly. We offer world-class logistical capabilities for label programs of all types. Our sophisticated, mobile-ready vendor managed inventory services eliminate stock-outs, maintain inventory to meet spikes in demand, and reduce your total cost of ownership.

Data-driven demand forecasts are utilized to minimize on-hand inventories while optimizing least-cost production models. Storage and fulfillment are managed through our nationwide network of in-house distribution centers. Comprehensive billing and reporting options provide clear visibility to costs, inventory levels and usage patterns. The result is a complete VMI solution that makes label program management easier for you.

Our earth-friendly label stocks give you an opportunity to advance your sustainability goals while also improving operational efficiency and reducing costs.

With our thin-stock labels, construction is up to 50% thinner, and you’ll use 27% fewer greenhouse gasses and create 26% less waste. They also require fewer roll changes, and lower storage and distribution costs.

Our linerless direct thermal labels eliminate the end product that is ordinarily thrown away. Liner waste is reduced 100%, rolls are 75% longer and labels can be cut to exactly the right length for every type of label needed, reducing the number of SKUs in use.

Fields marked with an asterisk (*) are required.