We are now four blogs into our extended look at the total cost of ownership (TCO) of durable industrial labels. The following topics have already been addressed:

This time around our topic is label liners. Keep reading below to learn how the choice of label liner will affect the total cost of ownership (TCO) of your durable industrial labels.

Label Liners Explained

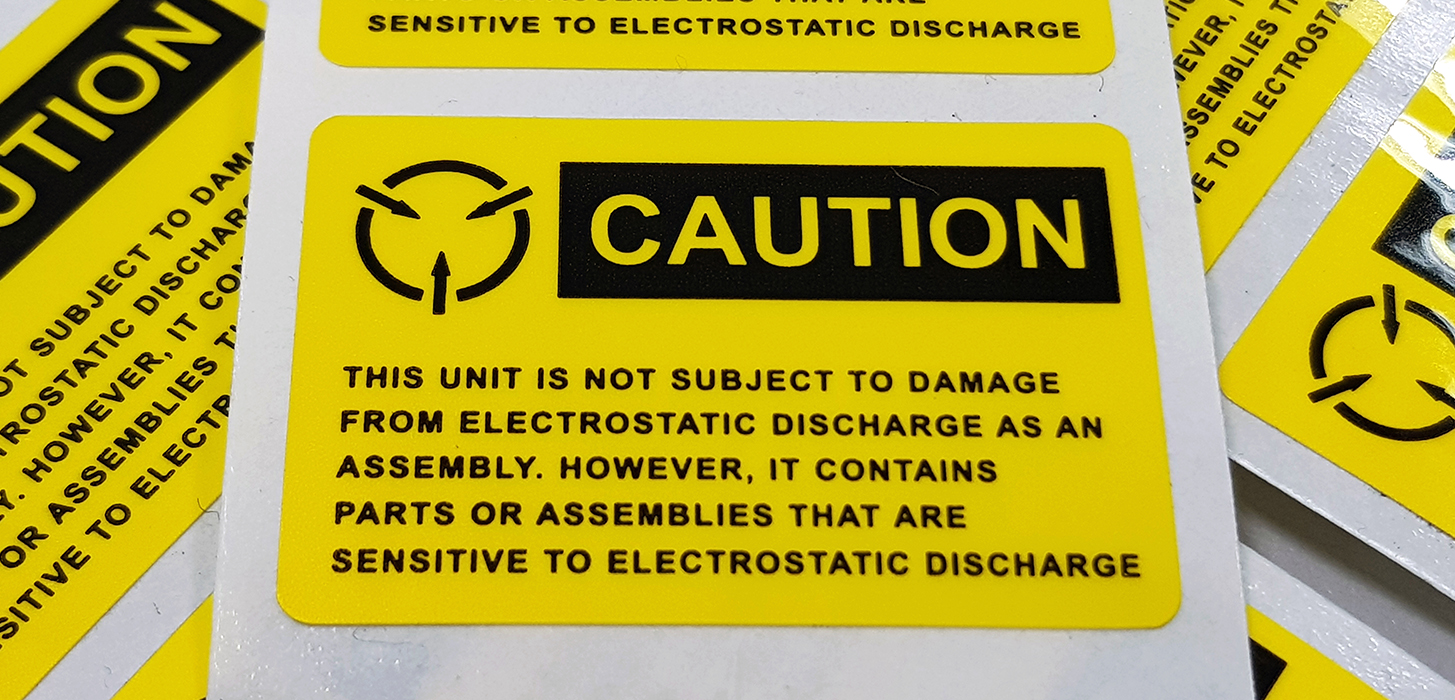

When you pick a label from a roll or sheet, have you ever wondered about the material that backs the adhesive? That backing material is called a label liner. The liner supports and protects the adhesive until the label is applied. Using the wrong type of liner can result in production delays or adhesion failure of the finished label – both of which drive up your total cost of ownership. There are various types of liners used for pressure-sensitive labels, each with unique characteristics to suit different applications.

Paper liners

Paper linersPaper liner materials are the most commonly used option due to their cost-effectiveness. They possess excellent stability and can hold up under various printing conditions. Here are some of the most common types:

- Glassine paper is a smooth, glossy and lightweight paper liner often used in applications where a smooth release surface is necessary. It is resistant to moisture and offers good dimensional stability. Glassine paper is commonly used for applications like food and beverage labeling and pharmaceuticals.

- Super calendered kraft (SCK) paper liners are known for their strength and stability. They are relatively thick and offer excellent flatness, making them suitable for label applications that require stiffness and durability. SCK liners are commonly used for product labeling in industries like chemicals and logistics.

- Clay-coated paper liners have a layer of clay coating on one side to enhance smoothness and printability. This type of liner is often used for labels that require high-quality printing, such as product branding and packaging labels.

- Semi-bleached paper liners offer a balance between strength and cost-effectiveness. They are commonly used in applications where label strength and rigidity are not as critical and cost considerations are more important.

- Layflat paper liners are designed to minimize curling and ensure that the label material lies flat when it is unwound from the roll. This is important in high-speed label application processes to prevent jams and misalignment.

- Recycled paper liners are made from recycled materials, offering an environmentally friendly option. They are used in applications where sustainability and eco-friendliness are key considerations.

Film liners

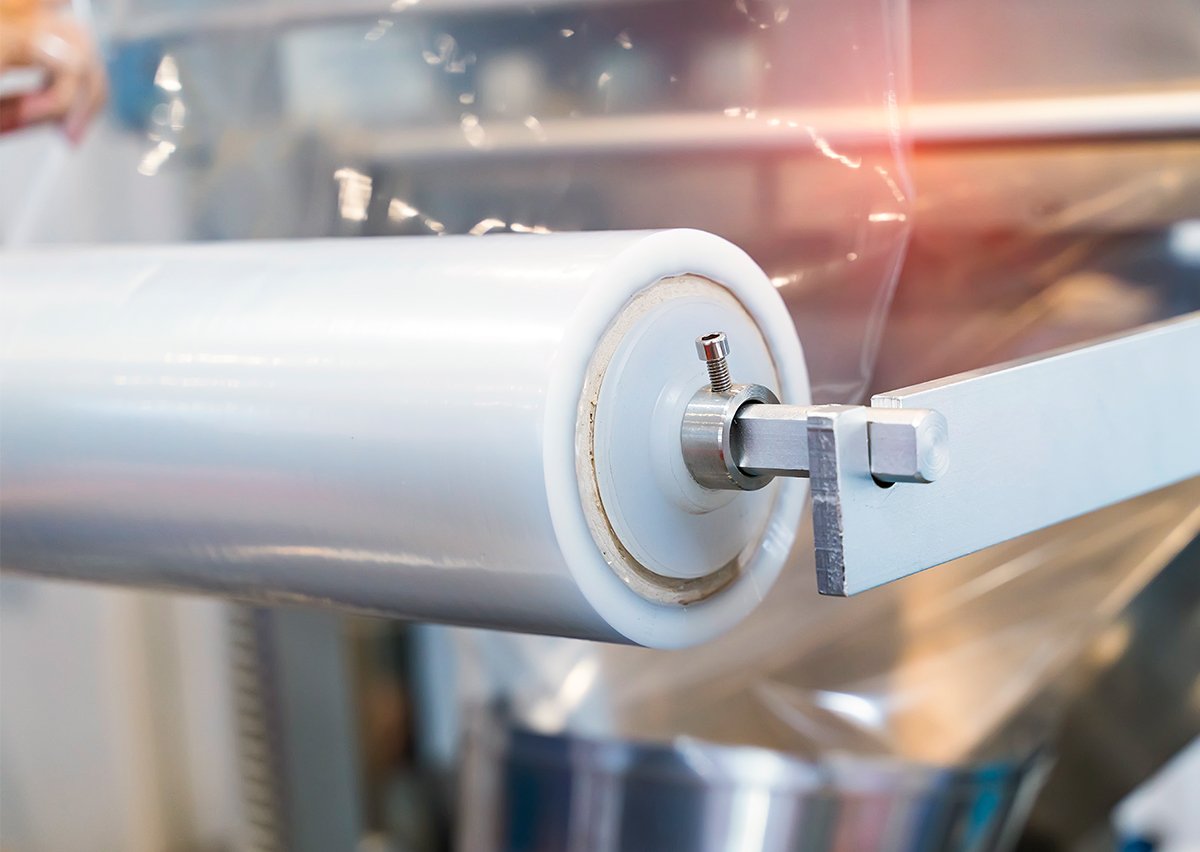

Film liner materials are more expensive but offer superior durability. Film liners can handle a range of printing and application conditions without costly downtime caused by breaks in the web. In addition, film liners are compatible with various types of printing including thermal transfer, thermal inkjet and laser printing. This means you can customize your label without sacrificing any strength or durability. These liners are typically made from materials like polyester (PET) or polypropylene (PP).

If your industrial operations require durable, high-quality labels that can stand up to demanding print and apply environments, film liners may be the better choice. Here are some common types of film liners for pressure-sensitive labels:

- Polyethylene (PE) film liners are known for their strength and tear resistance.

- Polyester (PET) film liners offer durability and resistance to harsh conditions and are available in both white and clear polyester. White PET film liners provide a bright, white background while clear PET film liners are used when a label needs to have a see-through look.

Linerless labels

Linerless labels are a type of label that eliminates the need for a liner altogether. Instead of a backing material, linerless labels are typically coated with a silicone release layer on one side. They are commonly used in industries including food and beverage, logistics, retail and manufacturing. This unique and highly versatile label construction offers many benefits.

- Linerless labels are environmentally friendly because they produce no liner waste.

- The absence of release liners reduces the overall material cost of linerless labels. This can translate into cost savings for businesses over time, especially for high-volume label applications.

- Linerless labels are often used in high-speed labeling processes due to their continuous format and ease of application. This can lead to increased efficiency and productivity, reducing the time and labor required for labeling tasks.

- Linerless labels allow for longer lengths on a roll since there is no need for space occupied by release liners.

- Longer lengths on rolls mean fewer roll changes during labeling processes, reducing downtime and increasing the efficiency of labeling equipment.

- Linerless labels can be printed and cut to the desired length on demand. This provides flexibility for variable data printing and allows businesses to customize label lengths for different products or applications.

- For businesses with limited storage capacity, linerless labels are advantageous because they take up less storage space compared to traditional labels with release liners.

The Best Liner for Industrial Labels

Choosing the right liner for your industrial labels is critical to reducing your total cost of ownership. Whether you opt for the traditional paper liner, the durable film liner or the linerless label, understanding the advantages and disadvantages of each type can help you make the right choice for your labeling project. The next time you peel off a label, remember that there's more to it than meets the eye – there's a liner supporting it all.

Label TCO Blog Series Continues

The next blog in this series will be devoted to inventory management. Join us again on the Taylor.com blog as we continue our exploration of the factors influencing TCO for durable industrial labels.

Taylor: Label Liners and Linerless Options

As an industry leader in durable labeling solutions, Taylor works with the various paper and film-based liner materials described here. We are also a leading proponent of linerless label technology and the many environmental benefits it creates. To learn more, please contact one of our labeling experts.

.png)