Packaging solutions for consumer packaged goods are an enormous industry and one particular segment is growing quickly. Sales of custom child-resistant packaging products are expected to grow at an annual rate of nearly 7% in the years ahead, reaching sales of $48 billion worldwide by 2032.

What is child-resistant packaging and why is it suddenly in such high demand? We’ve summarized some of the most important things to know about “CR” packaging. As explained below, the rapid growth is about much more than just child-proof cannabis packaging.

What is considered child-resistant packaging?

There is often confusion about so-called “childproof packaging regulations” and how child-resistant packaging came to be. What testing standards are used to evaluate certified child-resistant packaging? Also, who is ASTM and what governing body establishes child-resistant packaging regulations?

Back in 1970, the Poison Prevention Packaging Act (PPPA) mandated that certain substances be marketed in “special packaging” for added safety. Special packaging is defined by the U.S. Consumer Product Safety Commission (CPSC) as follows:

A package that is designed or constructed to be significantly difficult for children under five years of age to open or obtain a harmful amount of the contents within a reasonable time. The package must also not be difficult for adults to use properly.

The requirements governing child-resistant packaging are now established in the Code of Federal Regulations under CFR16.1700.20. All of the details of the testing process are detailed there including:

- The types of products that require CRP.

- The age-group breakdowns of the children and adults involved in testing.

- How the testing is conducted.

- How test results are interpreted as pass, fail or requiring more testing.

Regarding the question about ASTM child-resistant packaging, the American Society for Testing and Materials is an international organization that develops standards related to product quality and safety. Thousands of members from countries around the world collaborate to improve the performance of materials, products and processes.

While ASTM does not have the authority to enforce its standards, many corporations and government agencies require them to be followed. ASTM testing standards are followed in the testing and classification of child-resistant packaging as governed by the Consumer Product Safety Commission (CPSC).

Are childproof containers really childproof?

Different terminology is often used to describe this special type of packaging. Phrases like childproof packaging and childsafe packaging are sometimes used interchangeably with child-resistant packaging. Are these other terms accurate?

Actually, no. Those other terms can create a false sense of safety among consumers. As described above, child-resistant packaging is designed to be significantly difficult for children under five years old to open or obtain a harmful amount of the substance within a reasonable time. However, it is not entirely childproof. The Consumer Product Safety Commission itself stresses that no packaging can ever be guaranteed to be 100% childproof or childsafe.

The main purpose of child-resistant packaging is to reduce the risk of accidental poisoning by creating an additional barrier. Think of it as the last line of defense, not the first. While these packages are effective at reducing child poisoning rates — the original goal of the Poison Prevention Packaging Act back in 1970 — they are not truly childproof and child supervision is always necessary.

What types of packaging qualify as child-resistant?

The consumer packaged goods industry is extremely diverse and the range of packaging formats encountered by consumers each day is enormous. What are some of the most common child-resistant packaging technologies and how can you tell if a package is child-resistant?

Depending on the type of product being packaged, child-resistant packaging can take many different forms.

- The squeeze-and-turn safety caps often seen on medicine bottles require the user to squeeze the sides of the bottle and twist simultaneously. Snap caps require the user to orient the cap a certain way and to apply significant force to pop the cap off.

- Blister pack packaging uses individual “compartments,” often made of plastic or foil, to dispense pills or capsules individually. They may also include tear-resistant cardboard cartons and notches that hook onto the carton, requiring an additional step to remove the blister pack.

- Twist-and-lock caps on aerosol cans help to prevent accidental spraying by requiring the user to twist the top to unlock the nozzle. Some complex designs even require removing the cap and re-attaching it to operate the spray nozzle.

Special mention should be made of another packaging option — flexible packaging. Custom flexible packaging is surging in popularity and has emerged as one of the most popular custom packaging formats in recent years thanks to its light weight and ease of use. Child-resistant mylar bags and other types of child-resistant zipper pouches can combine three key attributes to provide an effective solution.

Flexible packaging films

The durable films used by flexible packaging manufacturers possess high barrier properties to keep the contents fresh, safe and secure.

Child-resistant zippers

Flexible packaging pouches with press-to-close zippers require special actions and dexterity to open, making them difficult for children but easy for adults.

Tamper-evident closures

Features like tear notches and heat seals above a press-to-close, child-resistant zipper provide an additional layer of security, indicating if the package has been opened previously.

How is cannabis changing child-resistant packaging?

Cannabis has not been mentioned thus far but is often associated with custom child-resistant packaging and custom flexible packaging in particular. Can the growth of CR packaging demand in the U.S. be traced to the cannabis industry specifically?

No doubt about it, the cannabis industry in the U.S. is expanding rapidly through legalization and growing consumer acceptance. This has created a surge in demand for child-resistant cannabis packaging as regulations mandate that cannabis products be sold in child-resistant packaging to prevent accidental ingestion by children.

However, cannabis is not the only industry driving demand for certified child-resistant packaging and custom flexible packaging specifically. Several other industries in the U.S. are major users of child-resistant flexible packaging due to the need to ensure consumer safety.

Pharmaceuticals

The pharmaceutical industry is perhaps the largest user of certified child-resistant packaging. Regulations mandate that prescription and over-the-counter medications be packaged in child-resistant containers to prevent unintended harm to children. When the proper flexible packaging closure is used, custom flexible packaging is one option.

Household Chemicals

Household chemicals, including cleaning products, detergents and pesticides, are frequently packaged in child-resistant flexible packaging. This helps prevent accidental poisoning and ensures that these potentially hazardous substances are kept out of reach of children.

Nicotine Products

The tobacco and nicotine products industry, including e-cigarettes and vaping products, also relies heavily on child-resistant packaging. This is to prevent children from accessing nicotine-containing products, which can be highly toxic.

Personal Care Products

Certain personal care products, such as cosmetics and skincare items that contain potentially harmful ingredients, can also be packaged in child-resistant flexible packaging. Again, it’s all about using the correct type of child-resistant zipper closure.

Custom Child-Resistant Flexible Packaging From Taylor

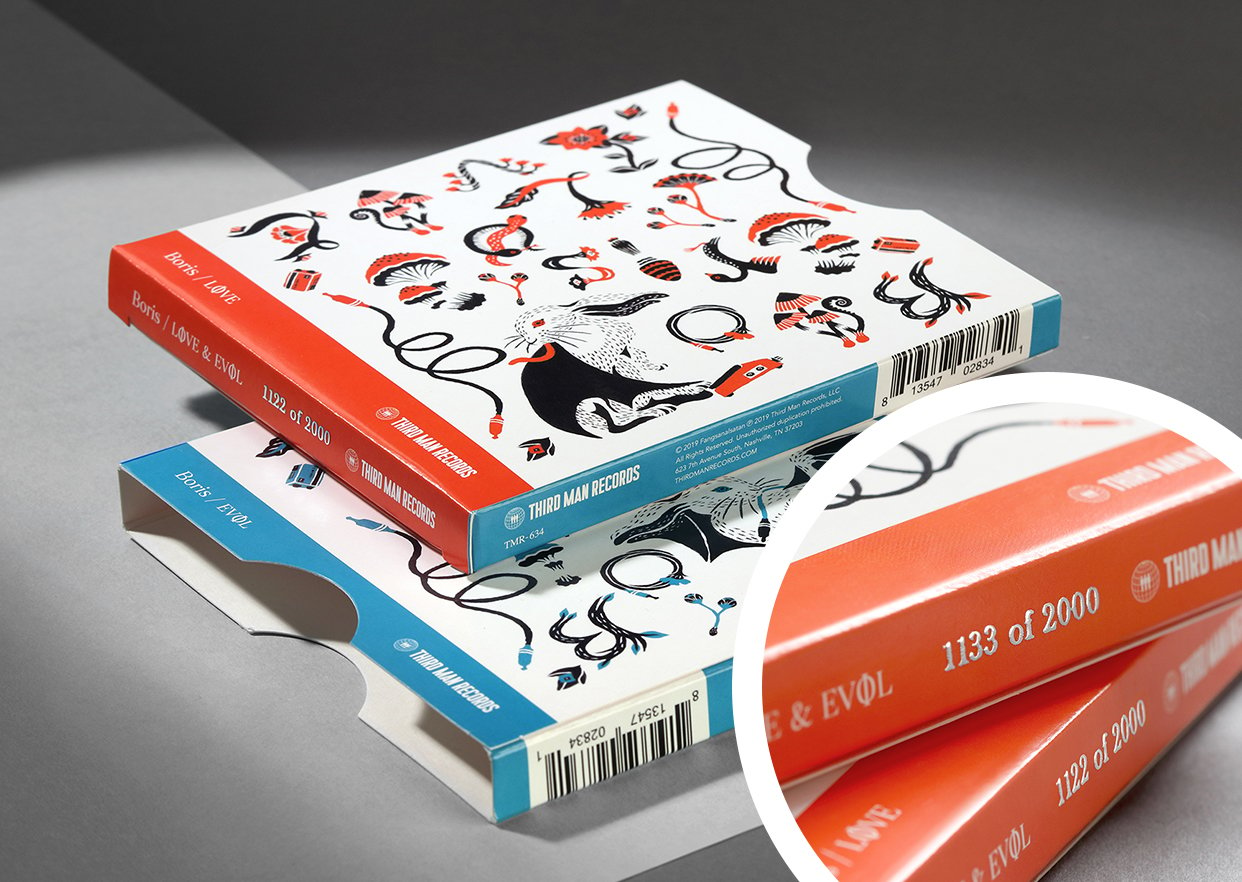

Many of the leading consumer brands you use each day rely on Taylor for their packaging and labeling. Our range of custom packaging and labeling solutions includes folding carton packaging and custom labels of every imaginable size and configuration.

We are also a flexible packaging manufacturer and offer the child-resistant zipper pouch formats described above. Taylor creates custom child-resistant flexible packaging solutions that have passed the rigorous laboratory tests outlined in CFR16.1700.20. Used for everything from nutraceuticals and cosmetics to household cleaners, cannabis and more, our certified child-resistant packaging conforms with all CPSC standards regarding Poison Prevention Packaging.

Contact a Taylor representative to learn more about our custom child-resistant packaging products.