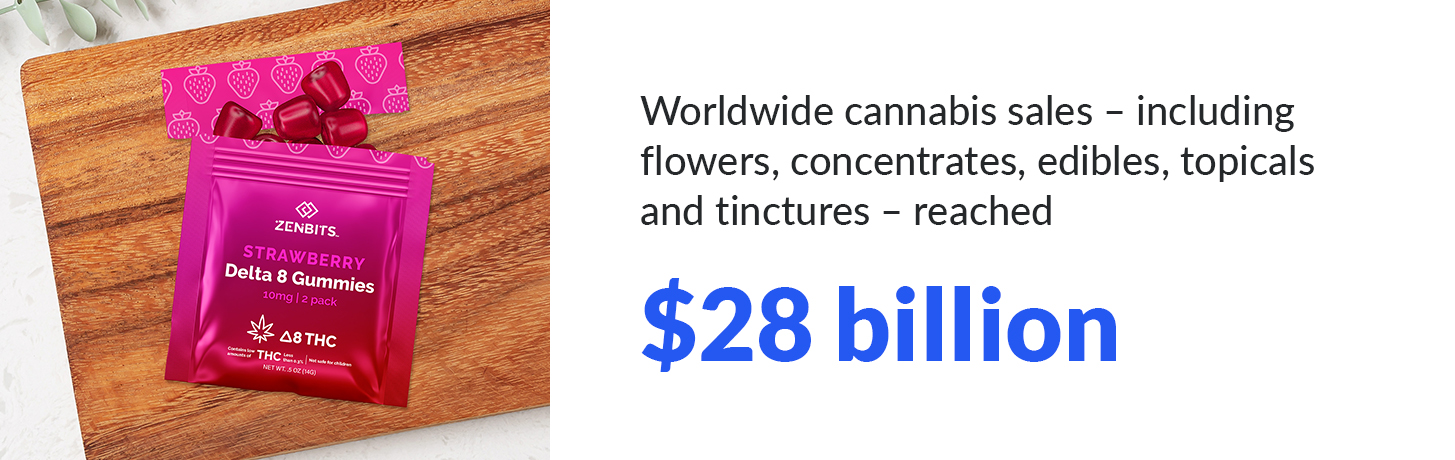

The cannabis industry is experiencing explosive growth thanks to a shift toward legalization. Worldwide cannabis sales – including flowers, concentrates, edibles, topicals and tinctures – reached $28 billion in 2022 and are on pace to top $80 billion by 2027.

Those products all need to be brought to market, of course, and the cannabis packaging market has blossomed in response. Now estimated to be expanding at a CAGR of more than 17%, the global cannabis packaging industry is expected to surpass $2.5 billion by 2032.

Done right, cannabis packaging enhances the consumer’s experience and creates brand loyalty. To remain one step ahead of your competition and grow market share, there are three trends to watch regarding your cannabis packaging decisions.

The Top 3 Cannabis Packaging Trends to Watch

1. Environmentally Friendly Solutions

Sustainability and environmental awareness are shaping consumer preferences like never before. Research shows that 77% of Americans are concerned about the environmental impact of the products they buy. This trend is especially strong among the youthful, socially conscious population now driving cannabis sales nationwide.

One environmental factor within the control of every cannabis producer is type of packaging used. In the spirit of “reduce, reuse and recycle,” there are a series of decision points for cannabis brands to consider.

Minimal Use of Raw Materials

The most environmentally sound use of any raw material is not to use it at all. Designs that reduce the amount of materials used (e.g., flexible packaging films, paperboard cartons, printed sales literature, etc.) automatically shrink the environmental footprint of bringing your product to market.

Efficiencies in the Supply Chain

Such minimization strategies generally have the added benefits of reduced weight and size. Less weight translates to less fuel consumed in the supply chain for shipment. Small, space-efficient packaging translates to fewer pallets to ship, fewer trucks needed to ship them, and less warehouse space that will be occupied.

Thinking Outside the Box

There’s more to the environmental impact of a package design than meets the eye. At first glance, the classic renewable and recyclable paperboard carton would seem to be “greener” than plastic-derived flexible packaging. However, the film used for pouches generally consumes less energy and water to manufacture than paperboard. It’s lighter and more compact than a paperboard box, reducing fuel consumption in the supply chain. And, it has a higher product-to-package ratio – a key measure of sustainability in consumer products.

2. Smart Features

The advent of smartphone technology has expanded the role of product packaging forever. Much more than just a delivery vehicle, the package can now function as an interactive device and an inseparable component of the brand experience.

Variable, data-driven digital printing makes it possible to generate unique QR codes and barcodes on each cannabis package. Whether applied to a carton, can or flexible pouch, these “smart package” features open the door to countless opportunities such as:

· Augmented reality experiences

· Coupons and incentives

· Expanded product information

· Interactive games

· Loyalty programs

· Product tracking and tracing

· Video content, and more

3. Product Security

The final trend revolves around the safety of the consumer and the security of the purchase transaction itself. Child-resistance is the first and most obvious consideration.

Since 1970, “special packaging” has been required by the U.S. Consumer Product Safety Commission (CPSC) for products that could potentially be harmful to children. More than 20 states now have laws on the books pertaining to cannabis packaging, many of them specifying the child-resistance standards that must be met.

However, child resistance is not the only consideration. Many states require that cannabis be sold in containers that are opaque. Some states specify double packaging for added safety or special warning messages to ensure the consumer knows what they are buying. Always research the unique state-by-state requirements before entering new markets.

Yet another layer of security pertains directly to your brand. Counterfeit cannabis products have emerged as a threat to consumers and producers alike. The National Cannabis Industry Association breaks counterfeiting down into two types:

Packaging Impersonation

Counterfeiters mimic the design, colors and labeling of an authentic brand in an attempt to pass off substandard products as the genuine article.

Product Tampering

The cannabis within the package is intentionally altered or manipulated, sometimes introducing harmful contaminants or affecting the potency of the product.

To beat the fraudsters at their own game, cannabis packaging manufacturers are engaging some of the same techniques that are used to keep currency safe from counterfeiters:

· Color-changing inks

· Digital watermarking

· Holograms

· Microtext

· Unique serial numbers

· Tamper-evident seals and banding

Taylor: Leading the Way in Cannabis Packaging

Taylor has delivered labeling and packaging solutions to consumer products manufacturers for decades and we apply that expertise to the cannabis industry.

Our flexible packaging capabilities are ideally suited for cannabis products. Taylor offers multiple types of barrier film, including opaque and transparent options. We also hold the critical CFR16.1700.20 certification for child-resistant Poison Prevention Packaging.

Looking for something other than a pouch? Taylor offers nearly everything that a cannabis producer might need to take a product to market including:

· Multi-ply expanded-content labels

· Blister packs

· Shrink sleeves, and more

Keep your brand one step ahead of the competition in the highly competitive cannabis marketplace – all while working with a single vendor partner. Contact a Taylor representative to learn about our many cannabis packaging solutions.