Have you ever seen a picture or advertisement that seemed to come to life? Perhaps the picture changed, appeared in 3D, displayed an animation or altered your perspective in some way. All of this happened simply by my moving the item in your hands from side to side or up and down.

Chances are you were looking at a piece of lenticular print. In this post, we will explore what lenticular printing is, the visual effects that are possible, the types of equipment used to create it, and the six most common uses in marketing.

Lenticular Printing Explained

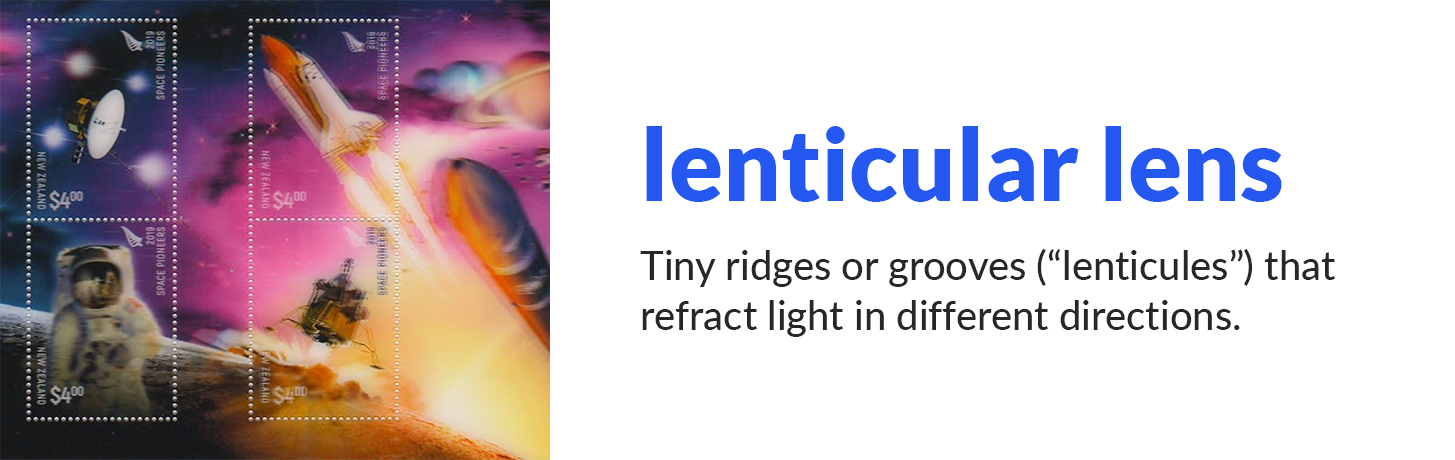

Lenticular printing is a process that uses a special kind of flat, clear plastic with a lens embossed on one side to produce two or more different images from a single printed sheet. The plastic is called a lenticular lens, meaning it has tiny ridges or grooves (“lenticules”) that refract light in different directions.

The technology has been around since the early 1900s but didn’t become practical until economical processes for extruding the lens and printing the images were developed. The prints themselves are lenticular prints and are sometimes called dimensional graphics, motion graphics or flip images.

Regardless of the name, it’s the combining of images beneath the lens that allows lenticular printing to create various visual effects. Perhaps the most impressive aspect is the sheer variety of effects possible:

3D

The various elements in the printed piece create the illusion of depth, producing a 3D image.

Flip

Two or more images are combined, producing an image that flips from one to another at varying view angles.

Zoom

Images, logos and text appear as a fluid transition in size or position to create an eye-catching motion when varying the view angle.

Animation

Also called full-motion video – in which a clip of a movie is mapped under the lens – images appear to move when viewed from different angles or distances.

Morphing

One image gradually transforms into another, such as when a person "morphs" into an animal.

Combination

It’s even possible to combine two effects on one piece. The combination of 3D and flips is most common but flips can also be added to morphs, zooms or animation effects.

Lenticular Printing Methods

Lenticular Printing Methods

Not just anyone can produce lenticular images. The lenticular printing process requires specialized materials and equipment.

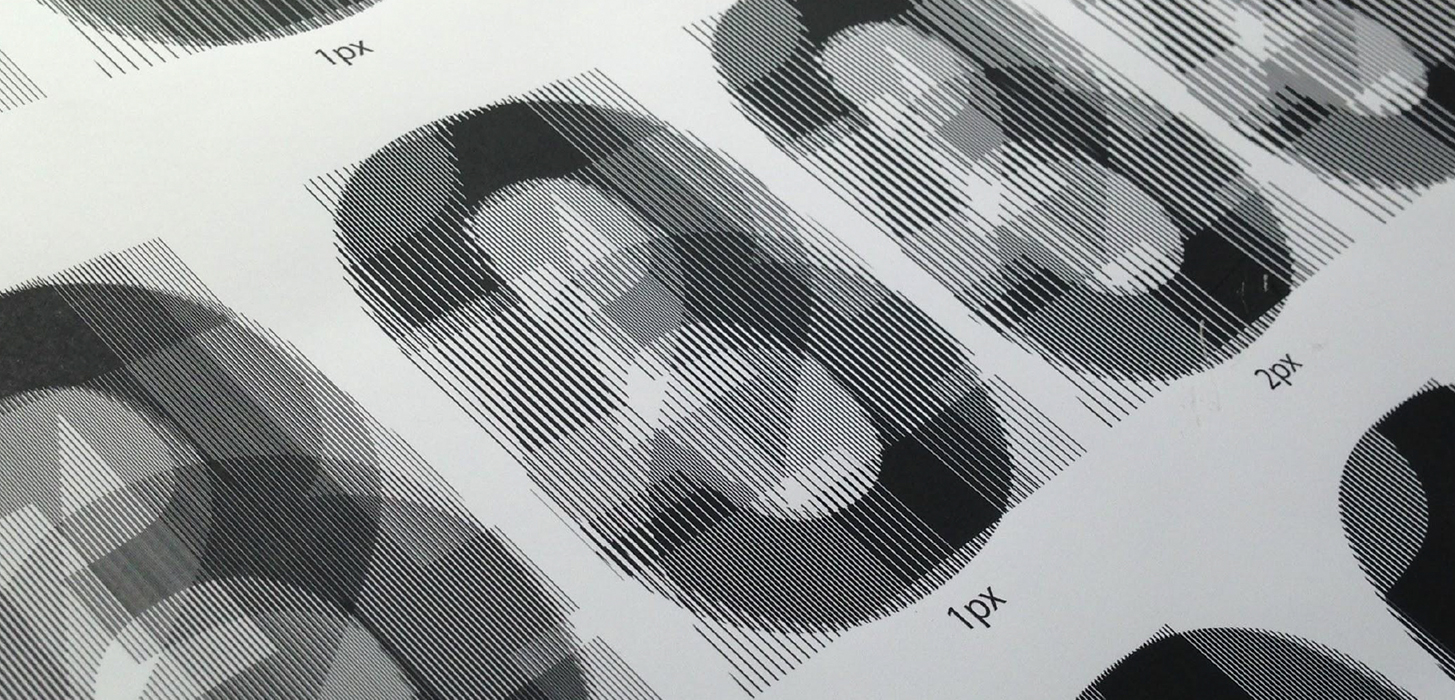

The lenticular images are often printed directly onto the plastic using UV inks.

· The lens is usually made of acrylic, PETG or APET, and the lens pitch – the frequency of lenses per inch – can range from 25 to 200 lines per inch.

· The printing requires high-resolution graphics, which are typically created using specialized combination software.

· Both offset and digital printing processes can be used but digital production is better suited for smaller print runs and more complex designs.

· Specialized finishing equipment can be used to laminate opaque backings, pressure-sensitive glues or in-moldable film.

6 Key Uses in Marketing

6 Key Uses in Marketing

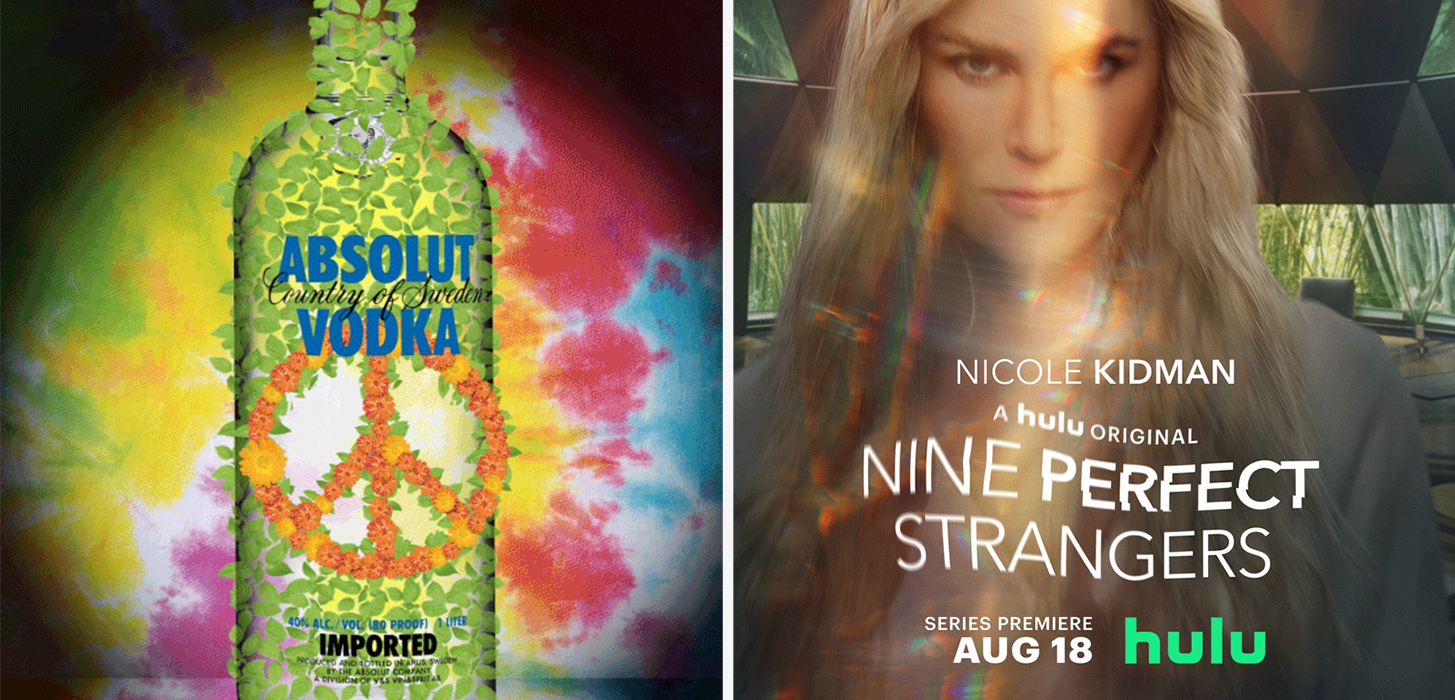

So, why go to the trouble to create a printed piece this way? It’s all about grabbing attention and creating a memorable impression on the viewer. When lenticular effects are used, the finished item is transformed from something flat and motionless into something that actually feels alive. Here are six common uses for lenticular printing in marketing:

1: Packaging

2: Signage

Posters and other signage media make a stronger impact when lenticular effects are incorporated.

3: Point-of-purchase displays

Adding a sense of motion or depth creates powerful in-store displays for products like cosmetics, electronics and toys.

4: Direct mail

Consumers are three times more likely to retain a piece of lenticular direct mail than a normal postcard or mailer.

Ordinary trade show materials like business cards and badges feel more special when they’re lenticular.

6: Collectibles

Lenticular print enhances the collectability of products like trading cards, cups and coasters, adding an air of exclusivity.

Taylor: Decades of Lenticular Printing Experience

Taylor: Decades of Lenticular Printing Experience

One of the largest graphic communications companies in North America, Taylor has long invested in the specialized technology required for lenticular printing. In fact, we have more than 20 years of experience in the category and offer:

· Specialized in-house lenticular design talent.

· In-depth knowledge of lenses and production processes.

· Digital halftone proofing, the most accurate lenticular prototypes in the industry.

These capabilities enable us to build stronger brands for our customers and to drive higher response rates and engagement levels. The lenticular products we produce include:

· Bookmarks

· Business cards

· Calendars

· Coasters

· Collectible souvenir cups

· Door hangers

· Gaming box covers

· Gift cards

· Journals

· LP covers

· Magnets

· Posters and signage clings

· Stickers

· Trading cards

· Video media covers

See for yourself what’s possible with lenticular print. Contact a Taylor representative to learn more.

See for yourself what’s possible with lenticular print. Contact a Taylor representative to learn more.