As noted in our past blogs on the topic of shrink sleeves, Mordor Intelligence has estimated the global market for “shrink and stretch sleeve labels” at more than $10 billion with a projected annual growth rate of 6.5% going forward. Shrink sleeve labeling offers several key advantages and consumer packaged goods manufacturers have taken note.

However, for those not familiar with the shrink sleeve labeling process, shrink sleeve sourcing can be a bit confusing. For example:

- What is a shrink sleeve?

- What is the difference between a shrink sleeve and a label?

- What material is used for shrink sleeve labeling?

- What types of containers can shrink sleeves be used on?

- How do you size a shrink sleeve?

This blog will explore shrink sleeve packaging including how shrink sleeve labels are different from other label formats. It will also list the most commonly used shrink sleeve materials and the types of containers that lend themselves to custom shrink sleeve labels. Finally, we will describe the all-important “shrink sleeve formula” and the method of sizing shrink sleeves to ensure that the correct size shrink wrap is applied to your product.

What is a shrink sleeve?

A shrink sleeve is a type of full-body label that wraps around a product container and conforms tightly to its shape when heat is applied. Made from heat-sensitive plastic film, shrink sleeves offer 360º coverage, making them ideal for eye-catching designs and detailed product information. Shrink sleeve labeling is especially popular in the beverage, cosmetics and household goods industries where shelf appeal is so critical.

Unlike traditional labels, shrink sleeve labels can fit a variety of container shapes — from curves to complex contours — and deliver functional benefits like tamper evidence and resistance to moisture. Shrink sleeve label packaging performs as beautifully as it looks.

What is the difference between a shrink sleeve and a label?

While all shrink sleeves are labels, not all labels are shrink sleeves. Traditional pressure-sensitive or glue-applied labels typically cover only a portion of a container’s surface, often the front or back. This places hard limits on design elements and branding decisions. In contrast, shrink sleeve labels offer full 360º coverage, wrapping entirely around the container and conforming to its shape.

The shrink sleeve labeling process itself is entirely different from that of pressure-sensitive or other adhesive labels. Shrink sleeves are printed on plastic film rather than the paper substrates most commonly used for ordinary labels. In simple terms, the process is as follows:

- A roll of heat-sensitive plastic film is printed with the label design.

- The film is either pre-cut into individual shrink sleeves or left in a continuous roll.

- These shrink sleeves are most often fed into an automated labeling machine, where each one is opened and positioned over the product container.

- Once the sleeve is in place, the container passes through a heat tunnel or steam chamber. The heat activates the film’s memory, causing it to shrink tightly around the container’s contours.

- The result is a seamless, form-fitting shrink sleeve label that adheres perfectly to even the most complex shapes.

What material is used for shrink sleeve labels?

As noted previously, shrink sleeve labels are made from specialized plastic films that shrink when heat is applied. The shrink sleeve materials used most often are PETG, PVC and OPS.

- PETG (polyethylene terephthalate glycol) is the most widely used material for shrink sleeve label packaging. It offers excellent clarity, high shrink rates and strong resistance to moisture and damage. PETG is ideal for complex container shapes.

- PVC (polyvinyl chloride) is cost-effective and easy to process, with good shrink performance. However, its chlorine content can make it somewhat less desirable from a sustainability standpoint.

- OPS (oriented polystyrene) provides a balance between cost and performance. While it offers good printability, it tends to be less flexible, limiting its use on highly contoured containers.

What types of containers can shrink sleeves be used on?

One of the biggest advantages of shrink sleeve labels is their versatility. From sleek beverage bottles to oddly shaped cosmetic jars, shrink sleeves can conform to nearly any shape, making them a go-to solution for brands seeking both form and function.

- The food and beverage, personal care, household products and pharmaceutical industries frequently use shrink sleeve label packaging to enhance shelf appeal and provide tamper-evident features. You’ll find them on everything from craft beverages, energy drinks and yogurt cups to shampoo, cleaning products and vitamins.

- Container types applicable to shrink sleeve packaging include bottles, cans, jars and tubs. Whether the containers are tall and cylindrical or short and contoured, shrink sleeve labels are unique in their ability to adapt to the curves, ridges and unusual geometries that traditional labels struggle to cover.

- Plastic, glass and metal containers are all compatible with the shrink sleeve labeling process. The key is to use a container rigid enough to withstand the shrink forces of the sleeve while also tolerating the heat of the shrink tunnel.

How do you size a shrink sleeve?

Perhaps the most critical step in the process for shrink sleeve services is getting the sizing just right. Unlike traditional labels that rely on an adhesive to stick to a container, shrink sleeves are designed to conform to the shape of the container itself. That means the shrink sleeve material must be carefully chosen to fit the container’s contours without wrinkling, tearing or sagging. It also means the shrink sleeve label that wraps the container must be precisely sized and cut.

How to choose shrink wrap size? The “shrink sleeve formula” for sizing shrink sleeves is actually a six-step process that’s equal parts art and science.

Step 1: Start with the container

The first step is to analyze the container itself. Shrink sleeve services take precise measurements of the container’s height, circumference and any unique features like curves, ridges or tapers. A 3D model or physical sample is often used to understand how the shrink film will behave during the shrinking process.

Step 2: Choose the right shrink film

Different shrink films (like PETG, PVC or OPS) have different shrink ratios — how much they contract when heat is applied. PETG, for example, can shrink up to 78% while OPS might shrink less. Knowing the film’s shrink characteristics helps determine how much larger the label should be printed before shrinking.

Step 3: Calculate the lay-flat width

The lay-flat width is the width of the shrink sleeve label in its finished, folded state before application. It’s calculated based on the container’s circumference. For example, if the container has a 200 mm circumference, the lay-flat width might be printed at approximately 103 mm to allow for proper shrinkage and alignment of the finished shrink sleeve labels.

Step 4: Account for distortion

Shrink sleeves don’t shrink uniformly, especially around curves or indentations. That’s where distortion mapping comes in. Using special software, shrink sleeve packaging services simulate how the label will shrink on the container and then adjust the artwork accordingly. This ensures that logos, text and images don’t warp or misalign during the shrinking process. (NOTE: Unsure how your graphics will look on the container? Call us to discuss. Distortion is a highly technical topic and Taylor specializes in consulting with customers on that type of issue.)

Step 5: Test and refine

Once the custom shrink sleeve label is sized and printed, it’s time to test. A prototype sleeve is applied to the container and passed through a heat tunnel or steam chamber. Engineers observe how the label conforms and make adjustments as needed. This trial-and-error phase is essential to fine-tune the fit and avoid issues like wrinkling or tearing.

Step 6: Final approval and production

After successful testing, the final label dimensions are locked in and full-scale production begins. The shrink sleeve label is now ready to deliver unbeatable visual impact and a flawless fit.

Taylor: Custom shrink sleeve labels for consumer packaging

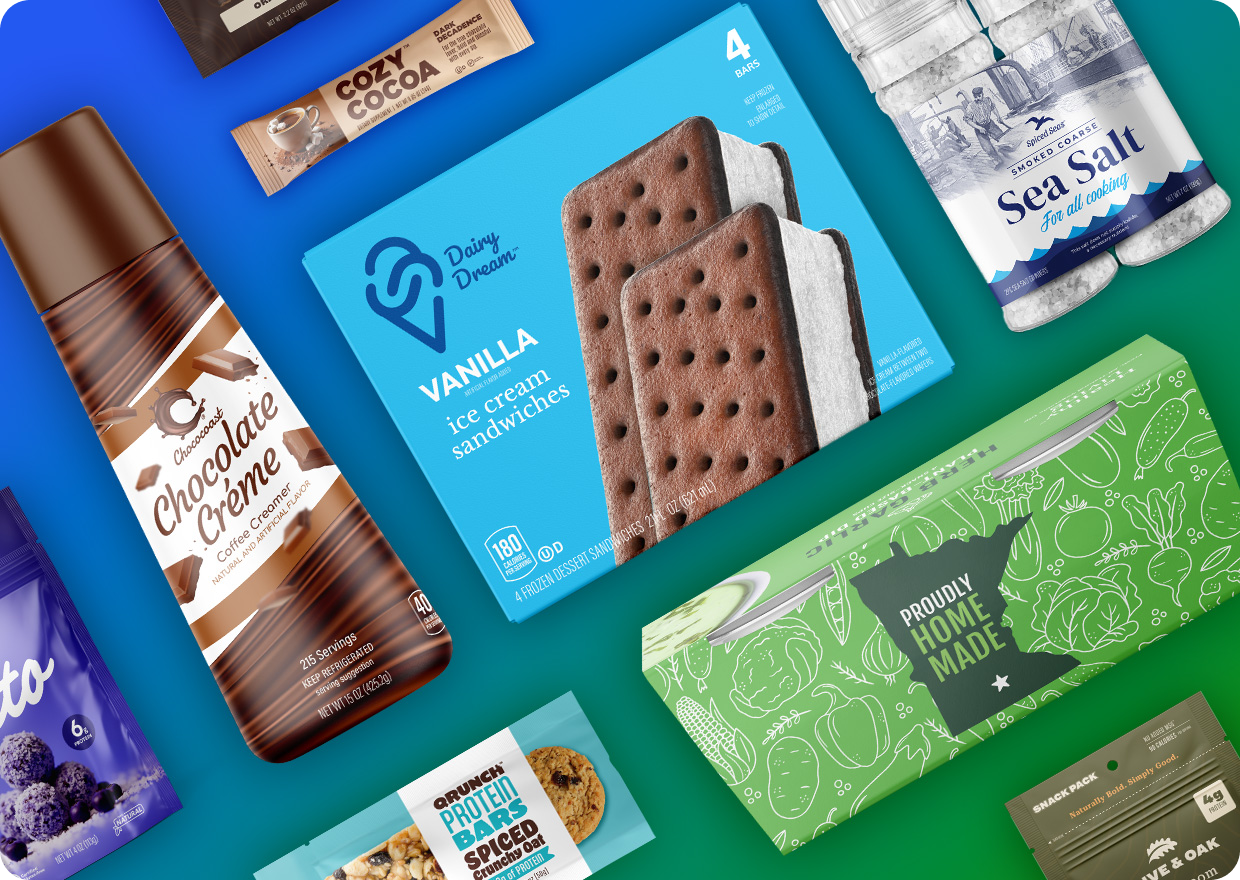

Taylor creates custom packaging and labeling solutions for many of the brands you use every day. This includes comprehensive shrink sleeve label packaging solutions for formats including:

- Full-body sleeves

- Multi-packs

- Individual sleeves or rolls

As described above, sizing shrink sleeves involves much more than measuring and printing. It’s a detailed process that demands a thorough understanding of materials, container geometry and heat dynamics. Taylor has invested in the tools and talent necessary to create shrink sleeve labels that fit like a glove and elevate the product’s shelf presence.

Best of all, everything needed to take your product to market is available through a single source:

- In-house design and prepress services

- 3D proofs and prototypes

- Digital, web offset and 10-color flexo print production technologies

- Cold foil, holographic effects, matte/gloss varnishes and other special finishes

- Referrals to shrink sleeve application equipment and bottle decorators

See for yourself what Taylor’s expertise with custom shrink sleeve labels can do for your brand. Contact a Taylor representative to learn more.