Our blog post titled Make Printing More Earth-Friendly and Cost-Effective explored five ways of increasing the sustainability and cost-efficiency of commercial print programs. Sustainable printing methods such as digital printing presses, soy-based inks and low-VOC coatings were among the recommendations. This time, we look at an emerging technology that’s raising the sustainability of warehousing and distribution services worldwide – and advancing the greater cause of sustainable packaging. Along the way, it’s also changing the economics of the entire shipping and fulfillment process.

CVP supports the sustainable packaging movement

Continuously variable packaging, or CVP, reduces the raw materials and fuel consumed across the entire distribution chain. It also creates process efficiencies that dramatically reduce costs for shippers.

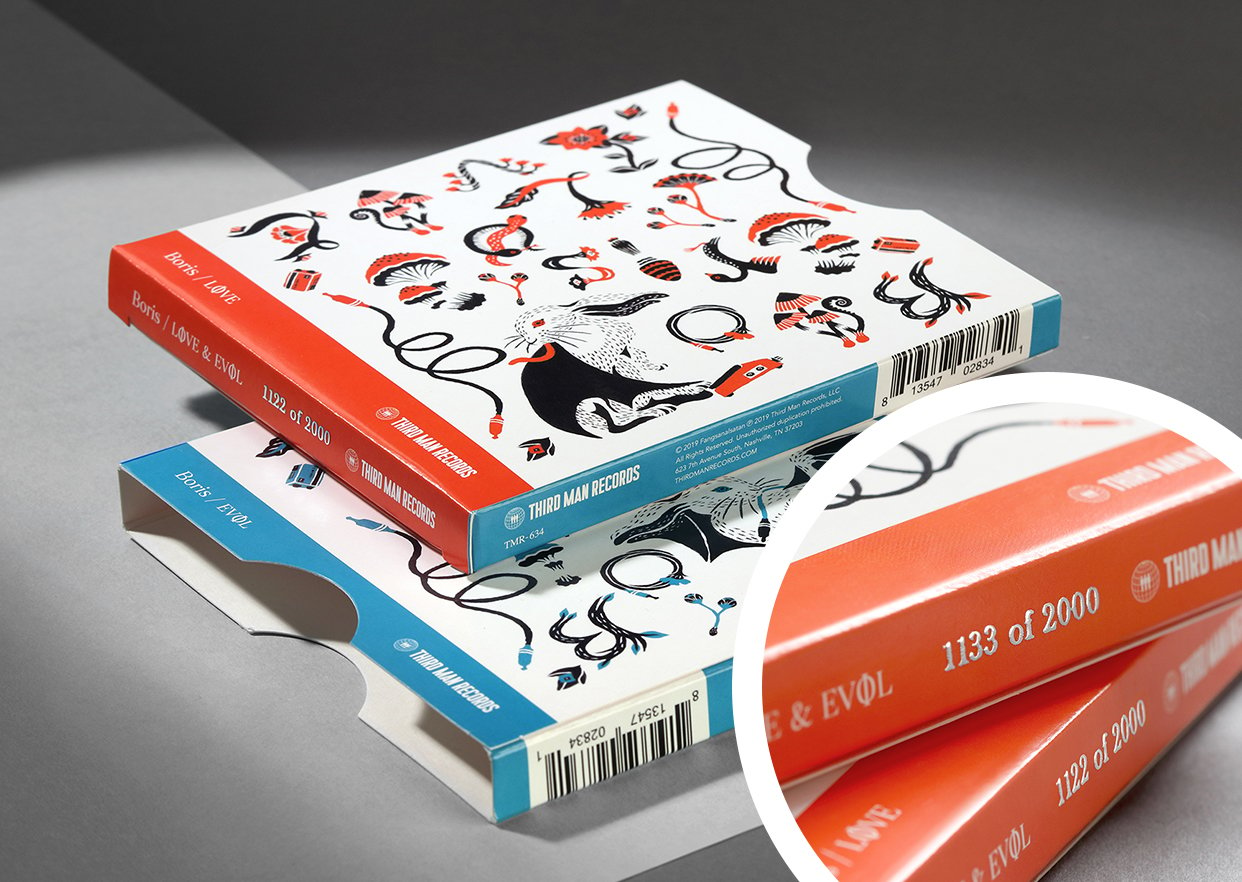

The concept is simple. With CVP, products are no longer packed into standard-size boxes with backfill padding to take up the excess space. Instead, boxes are created individually in the exact size and shape needed. As shown in this video from Neopost, multiple items can be stacked and packed in one parcel. Product literature can be added as well. The items are then automatically packaged as a custom-sized parcel is created, filled, folded and labeled in one pass.

The result is a shipping parcel that is as small and light as possible. Manual labor is also largely eliminated. It’s a classic win/win for both sustainable packaging and cost-efficiency. Keep reading to learn how continuously variable packaging saves the earth and money four ways.

#1: CVP ships product, not air

The four R’s of sustainability emphasize the need to reduce, reuse, recycle and renew. Continuously variable packaging is a prime example of “reduce.” CVP has been shown to reduce the amount of space inside parcels by up to 50%. Multiple items are combined in a single parcel if necessary and the box is then automatically sized to the smallest outer dimensions possible. Thus, shippers are shipping more product and less air in each parcel. Not surprisingly, this breakthrough in sustainable packaging has a dramatic impact on the environmental footprint of the distribution chain:

- More parcels can be loaded on each truck.

- More parcels per truck means fewer trucks.

- Fewer trucks means less fuel consumed.

As noted in our prior post, roughly 6% of total greenhouse gas emissions in the U.S. are from semi trucks. Imagine how much could that figure be reduced if all parcels were 50% smaller dimensionally. It also dramatically improves cost efficiency. CVP has been shown to reduce shipping costs up to 45%, a figure that is sure to capture the attention of ecommerce companies.

#2: CVP uses fewer raw materials

The “reduce” R is also present in the raw materials consumed by CVP. Since each parcel is only as large as it needs to be, less carton packaging material is consumed. Estimates show that 29% less raw carton material is needed when parcels are automatically sized by CVP.

There’s also the matter of backfill padding. Since a CVP-generated box is exactly the right size, there is no excess space inside the parcel that would allow contents to shift. No excess space means no backfill padding is required. In effect, CVP eliminates 100% of backfill padding materials. No more brown paper, bubble wrap, packing peanuts or plastic air pillows to fill the “slop” inside a parcel.

The combination of these two factors also reduces the volume of solid waste generated by consumers. According to the EPA, containers and packaging make up 28% of the total municipal solid waste stream in the U.S. How much of that waste could be eliminated if all parcels used 29% less carton material and 100% less backfill?

Finally, using less carton material and no backfill obviously means less weight per item shipped. No statistics are available to estimate the fuel savings of shipping smaller, unpadded parcels. However, considering that 87 billion parcels were shipped worldwide in 2018, the cumulative effect of this new sustainable packaging technology would be significant.

#3: CVP requires less labor

The economic benefits of continuously variable packaging are especially noteworthy in regard to labor. Boxing, taping/sealing, weighing and labeling processes are all automated and performed in-line by the CVP equipment. The net effect is an estimated 88% reduction in labor costs due to the elimination of most manual handling.

As an added benefit, CVP is estimated to be 10 times faster than manual packing processes. The value of such speed to market is difficult to quantify and would vary by industry. Suffice to say, an ecommerce company that can pack and ship products 10 times faster than the competition will have a tremendous strategic advantage.

#4: CVP minimizes return shipments

The automated, computer-driven in-line process of CVP also minimizes return shipments. Brick-and-mortar retailers commonly see purchase return rates of 8% to 10%. Ecommerce companies, in contrast, generally expect 20% of items to be returned. This is a significant drain on the bottom line.

Logically, the vast majority of ecommerce returns are due to people returning items they could not see, handle or try on beforehand. However, a nagging portion of that 20% is due to packaging and labeling errors by warehouse workers. Since CVP uses digital technology to “match” product with carton and carton with label, such errors are effectively eliminated.

This reduces costs for the ecommerce company and boosts their bottom line but there is an environmental aspect as well. Mislabeled parcels require fuel and other resources for two trips through the distribution chain: one outbound and one inbound as a return. By preventing unnecessary returns, those inbound trips go away – and the sustainable packaging movement chalks up yet another win.

A leader in warehousing and fulfillment technology

A leader in warehousing and fulfillment technology

Taylor maintains 1.7 million square feet of warehousing and distribution space and fulfills 5.3 million orders annually for customers throughout North America. From cold chain distribution products and complex kitting services to direct-to-consumer fulfillment services and more, Taylor is able to manage the most complex logistical challenge. We invest in the latest technology – such as continuously variable packaging – to ensure that we offer best-in-class sustainable packaging alternatives and cost-efficiency for our customers.

However, the most sustainable use of any raw material is to not use it at all. The third and final blog post in this series will look beyond sustainable printing and sustainable packaging to the world of digital. Innovative applications of digital technology continue to replace printed communications and in-person interaction. Come back next time as we look at emerging communications technologies that help companies attract and engage consumers in “greener” ways.

Other parts in the series

Part 1, Make Printing More Earth-Friendly and Cost-Effective in These 5 Ways