You’ve probably heard that “neither snow nor rain nor heat nor gloom of night” will slow your Postal Service delivery. In today’s demanding world of pharmaceutical logistics, the elements of nature can’t ever be allowed to risk safe drug deliveries either.

Temperature-sensitive drugs like insulin, vaccinations and inhalers must be temperature controlled from the moment they’re manufactured to the moment they make contact with the body. If delivering meds on time and on temperature is the goal, cold chain shipping is how pharmacies meet that goal.

Pharmaceutical cold chain shipping techniques have advanced rapidly, and new technologies are constantly improving how sensitive drugs can be both temperature controlled and environmentally responsible. Recyclable gel packs, insulated natural packing materials, temperature monitoring strips, and even weather-predicting algorithms are all tools to limit temperature exposure and environmental impact.

Taylor, a leader in kitting, fulfillment and cold chain distribution, wanted to better understand the best practices, technologies and thinking that pharmacies use to keep drugs temperature controlled and effective.

Taylor hired an independent research firm to survey a random sample of 155 Pharmacy Leaders about their approach to cold chain distribution for pharmaceuticals. The study’s margin of error is +/-6% at the 95% confidence level.

Cold Chain Study Highlights

Pharmacies constantly seek more reliable drug shipment temperature controls.

98% of Pharmacy Leaders say managing cold chain delivery risk is a top priority.

Pharmacies today want cold chain drug shipments on a regular schedule.

90% of Pharmacy Leaders prefer to have a routine, daily delivery rather than sporadic, unannounced deliveries.

Uncertified cold chain shippers are risky for pharmacies.

89% of Pharmacy Leaders say that receiving drug shipments from vendors who aren’t certified would be a serious risk to their business and patients.

A close relationship between shipper and pharmacy is key to safety.

Pharmacy Leaders say that a close relationship with their cold chain distribution vendor increases drug safety by an average of 70%.

The large majority of pharmacies want just one cold chain shipping supplier.

88% of Pharmacy Leaders say they prefer to use just one source for all their cold chain supplies.

Pharmacies prioritize consistent branding and pricing across locations.

Pharmacies prioritize consistent branding and pricing across locations.

86% of Pharmacy Leaders say their products have consistent branding and costs from location to location.

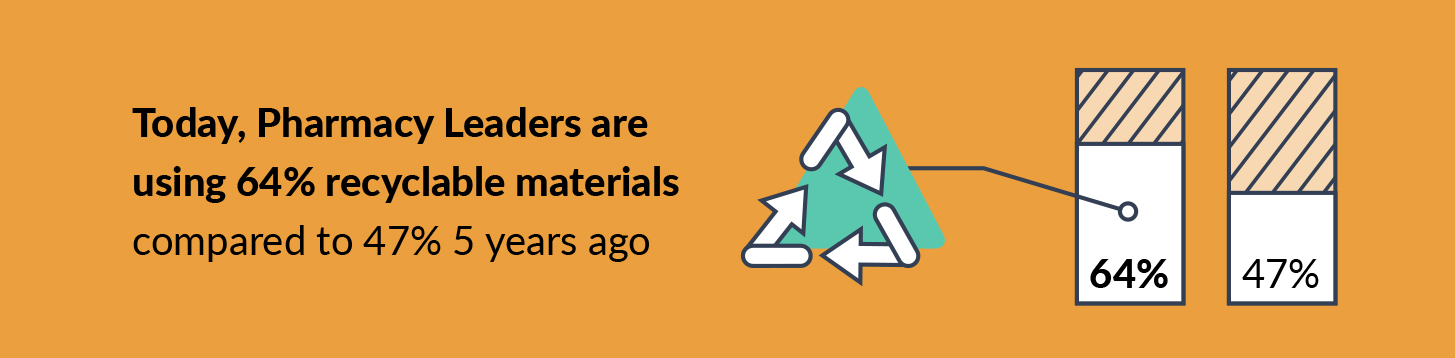

Cold chain packaging is more recyclable than 5 years ago.

Pharmacy Leaders today use 64% recyclable materials compared to 47% five years ago.

Even senior pharmacy staff need better cold chain knowledge.

Even senior pharmacy staff need better cold chain knowledge.

Only 60% of Pharmacy Leaders say they deeply understand the best practices of cold chain distribution.

Using just one cold chain shipper drives best practices.

Pharmacy Leaders who have centralized their shipping to one main source are nearly 2x more knowledgeable than those who haven’t about the best practices of cold chain distribution.

Pharmacies expect frequent packaging diagram testing.

On average, Pharmacy Leaders want their packaging diagrams tested at least every six months.

Pharmacy Leaders want fulfillment vendors to take the lead on packaging sustainability.

79% of Pharmacy Leaders say they expect their fulfillment vendors to proactively find ways to make their packaging more sustainable.

Recyclability tops the list of cold chain goals in 2022-2023.

Recyclability tops the list of cold chain goals in 2022-2023.

The top cold chain packaging goal of Pharmacy Leaders in 2022-2023 is high recyclability.

Learn more about Taylor Cold Chain services

Temperature strips are the #1 way pharmacies check for drug shipment safety.

Temp strips were the technology most mentioned by pharmacies to measure the safety of temperature-sensitive medications.

Certifications are vital to cold chain shipper reputation.

The top quality that Pharmacy Leaders require of a shipping vendor is certifications.

Modern temperature-controlled shipping tech is a “must have” for cold chain fulfillment partners.

60% of Pharmacy Leaders won’t do business with a fulfillment vendor that doesn’t use the most modern temperature-controlled shipping methods.

An extensive warehouse footprint is crucial for pharmacy fulfillment providers.

58% of Pharmacy Leaders won’t do business with a fulfillment vendor that doesn’t have an extensive warehouse footprint across the U.S.

Pharmacies want fulfillment providers to deliver SKUs consistently.

Pharmacies want fulfillment providers to deliver SKUs consistently.

59% of Pharmacy Leaders won’t do business with a fulfillment vendor that can’t deliver the same SKUs to every pharmacy location.

Download a report infographic to share with colleagues.

The tight labor market is straining drug shipment safety.

53% of Pharmacy Leaders say staffing shortages are limiting their ability to detect deliveries that don’t meet temperature standards.

Packaging efficiency and weight are top pharmacy priorities.

74% of Pharmacy Leaders say longer cooling times without increasing weight is one of their top five goals.

The Top 3 Priorities in Cold Chain Shipping

The concerns and preferences of Pharmacy Leaders sampled for this study were remarkably consistent. The three main takeaways of this study are as follows:

- Pharmacies seek to limit the number of shipping vendors they work with while increasing their collaboration in package design and best practices.

- Pharmacies are working diligently to support environmentally sustainable packing supplies while maintaining temperature consistency.

- Pharmacies want to work with shippers who can deliver at regular intervals, take a proactive approach to package design, are certified, and have a broad national footprint.

Taylor: A Leader in Cold Chain Distribution

Taylor is a leading provider of cold chain, with more than 20 years of experience and a network of 34 cold chain warehousing and distribution facilities. Want to improve your cold chain shipping program? Contact Taylor to learn more.